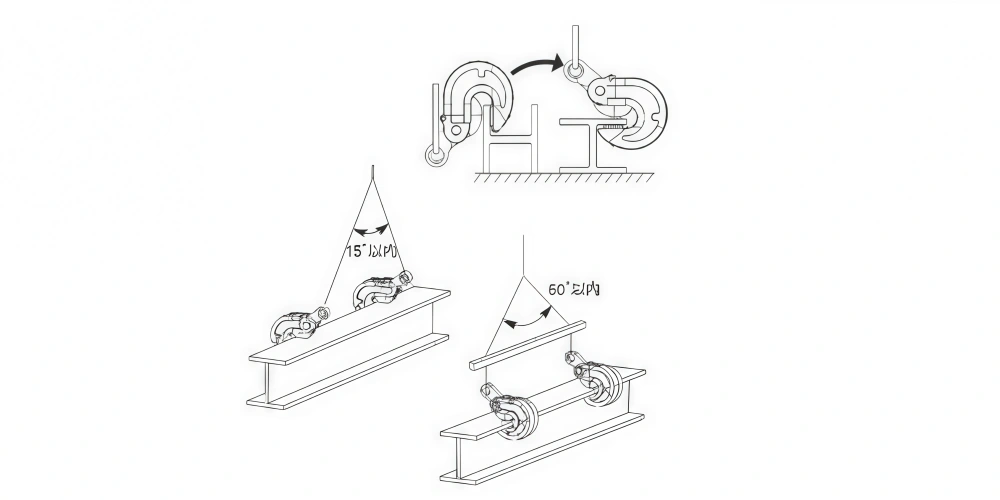

STEEL PLATE LIFTING CLAMP DRAWING

PLATE LIFTING CLAMP SPECIFICATIONS

| Model | WLL (tons)per pair | Jaw Opening(mm) | Weight(kg) |

| DFM1 | 1.0 | 0-15 | 2.5 |

| DFM2 | 2.0 | 0-20 | 5.5 |

| DFM3 | 3.0 | 0-30 | 8 |

| DFM5 | 5.0 | 0-50 | 12.5 |

| DFM10 | 10.0 | 0-60 | 26 |

INFORMATION OF STEEL PLATE CLAMP FOR LIFTING

-

Working Load Limit (WLL):

1-10T, suitable for various lifting and turning operations of steel plates and profile bars. -

Applications:

Ideal for horizontal lifting and flipping of steel plates and profiled bars, commonly used in construction, steel manufacturing, and warehousing. -

Design & Construction:

The clamp is compact, lightweight, and easy to operate, making it ideal for quick, efficient lifting. Major components are made from high-quality alloy steel molds, heat-treated for maximum strength and durability. -

Usage:

The single turn clamp can be used individually for lifting operations, but when performing horizontal lifting, it must be used with a beam to ensure safety and stability.

INSTRUCTIONS & CAUTIONS

Maximum Hardness of Steel Plates

When using the DFM turn clamp, ensure that the steel plates being lifted have a maximum hardness of 37HrC (345 HB, 1166 N/mm²). The clamp is designed to handle plates within this hardness range, and exceeding this limit could damage the clamp or make lifting unsafe.

Ambient Temperature Range

The clamp can be used in ambient conditions ranging from -40°C to +100°C. If you are working outside this temperature range, it may affect the clamp’s performance and safety. Always ensure the working environment is within these limits for optimal operation.

Avoid Overloading

Never overload the clamp. Always adhere to the working load limit (WLL), as overloading the clamp can result in failure or damage. During lifting, use only one clamp for each piece and ensure the weight is properly distributed to prevent stress on the equipment.

Safety Precautions During Lifting

Keep a safe distance while raising or lowering loads. Ensure that no one is positioned underneath the load at any time. Welding to the clamp is strictly forbidden, as it can negatively affect the clamp’s strength and durability, potentially leading to safety hazards.

OUR ADVANTAGES

European Quality Certification

We offer products that are certified with TUV, CE, and GS European quality standards, ensuring that our equipment meets the highest safety and reliability requirements. Our customers can trust that they’re receiving top-tier products that comply with global safety regulations.

Comprehensive Machinery Test Reports

Every product we supply comes with a detailed machinery test report, offering full transparency. This ensures that you can verify the quality and performance of each item before use. Our test reports help our customers make informed decisions, avoiding any surprises during operation.

Customizable Packaging

To fit your business needs, we offer customizable packaging options. Our standard paper carton packaging is sturdy, but we can tailor the packaging to suit your preferences, whether for branding, specific protection, or space-saving purposes. This flexibility ensures we meet the specific demands of wholesalers, suppliers, and large markets.

Reliable After-Sales Support

We don’t just sell products; we offer ongoing after-sales support to ensure long-term satisfaction. Whether you need maintenance advice, spare parts, or operational guidance, our team is always ready to help. This commitment to customer support sets us apart from other manufacturers.

FAQ

What is a DFM turn clamp and how does it work?

A DFM turn clamp is a versatile, heavy-duty clamping device used for securing parts and materials in various applications. It features a rotating handle for easy tightening and loosening. These clamps are perfect for industries requiring secure fastening of components in manufacturing, assembly, or maintenance. Their adjustable design ensures a tight hold, improving productivity and efficiency.

Are DFM turn clamps suitable for large-scale production lines?

Yes, DFM turn clamps are perfect for large-scale production lines due to their speed and ease of use. Their quick-action design allows workers to clamp and release parts efficiently, increasing throughput without sacrificing security. These clamps are built to withstand continuous use in high-demand environments, making them an excellent choice for manufacturing and assembly lines.

How do I install a DFM turn clamp?

-

Mount the Base: Securely mount the clamp’s base to the surface or fixture where you need the clamp.

-

Position the Clamping Arm: Adjust the clamping arm to the desired location.

-

Tighten the Turn Handle: Rotate the turn handle to tighten the clamp and ensure a firm hold.

-

No Complex Tools Needed: The adjustable design eliminates the need for complex tools, making installation quick and easy.

-

Need Help? Our customer service team can provide detailed installation instructions for added support.

How much weight can a DFM turn clamp support?

DFM turn clamps are designed for high-load applications. The exact weight capacity depends on the model, but they typically support loads ranging from hundreds to thousands of pounds. For precise specifications, you can refer to the product’s technical data sheet or consult with our sales team to ensure the clamp meets your requirements for heavy-duty use.

How can I place a bulk order for DFM turn clamps?

-

Contact Our Sales Team: Reach out to our sales team with your desired quantities and specifications.

-

Get Competitive Pricing: We offer competitive pricing for wholesale orders to help you save costs.

-

Product Selection Assistance: Our team will assist you in selecting the right DFM turn clamps for your needs.

-

Shipping and Delivery: We will coordinate shipping and delivery schedules based on your requirements.

-

Ensure Sufficient Stock: Bulk ordering ensures you have enough clamps for ongoing projects, avoiding delays.

Do DFM turn clamps come with a warranty?

Yes, DFM turn clamps come with a standard warranty covering defects in material and workmanship. Our clamps are built to last, and we stand behind the quality of our products. If you encounter any issues within the warranty period, our customer service team will work with you to resolve the problem and ensure your satisfaction.

Can DFM turn clamps be used for non-standard applications?

Yes, DFM turn clamps are highly versatile and can be adapted for non-standard applications. Their adjustable design and customizable features make them perfect for specialized uses. Whether you need a unique clamping solution or need to integrate them into custom machinery, our team can help create a tailored solution that meets your specific needs.