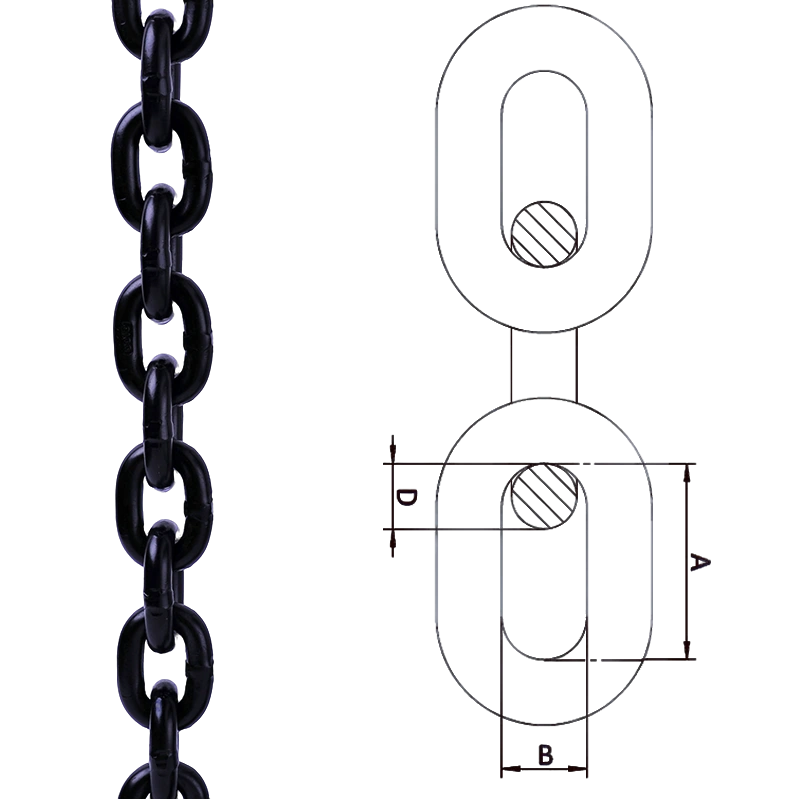

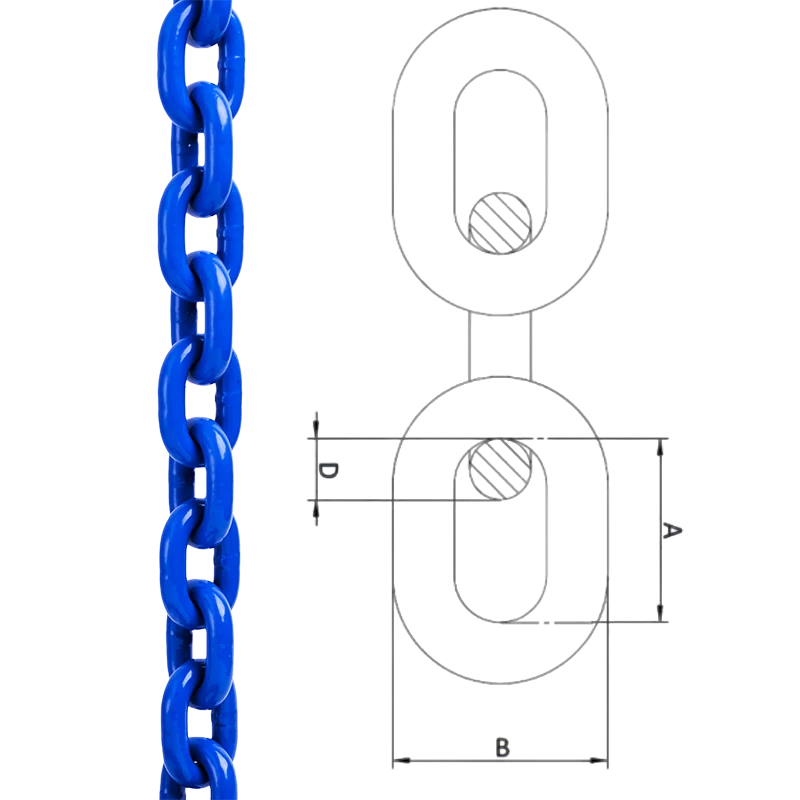

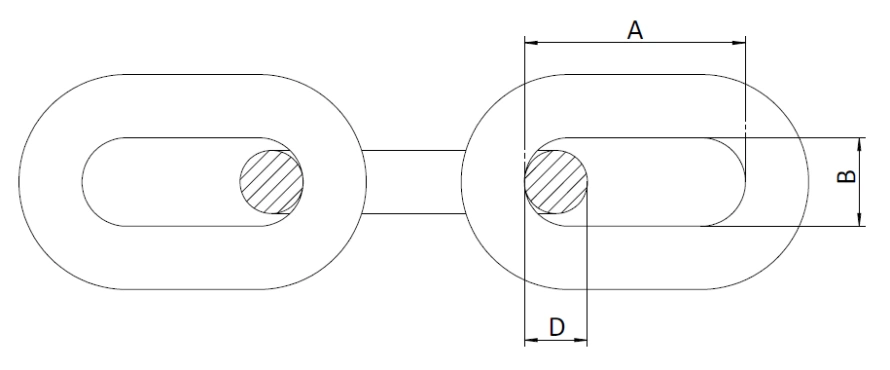

DIAGRAMS of GRADE 43 CHAIN

G43 CHAIN SPECIFICATIONS

| NOMINAL SIZE | MATERIAL DIAMETER | WORKING LOAD LIMIT | PROOF TEST(MIN) | BREAKING FORCE MIN | INSIDE LENGTH | INSIDE WIDTH | |||||||

| MM | IN | MM | IN | KG | LBS | KN | LBS | KN | LBS | MM | IN | MM | IN |

| 7 | 1/4 | 7 | 0.276 | 1180 | 2600 | 17.3 | 3900 | 34.6 | 7800 | 31.5 | 1.24 | 9.8 | 0.38 |

| 8.7 | 5/16 | 8.7 | 0.343 | 1770 | 3900 | 26 | 5850 | 52 | 11700 | 32.8 | 1.29 | 11.2 | 0.44 |

| 10 | 3/8 | 10.3 | 0.406 | 2450 | 5400 | 36 | 8100 | 72 | 16200 | 35 | 1.38 | 14 | 0.55 |

| 11.9 | 7/16 | 11.9 | 0.468 | 3270 | 7200 | 48 | 10800 | 96 | 21600 | 41.6 | 1.64 | 16.6 | 0.65 |

| 13 | 1/2 | 13.5 | 0.531 | 4170 | 9200 | 61.3 | 13800 | 122.6 | 27600 | 45.5 | 1.79 | 18.2 | 0.72 |

| 16 | 5/8 | 16 | 0.63 | 5910 | 13000 | 86.5 | 19500 | 173 | 39000 | 56 | 2.2 | 20 | 0.79 |

| 20 | 3/4 | 20 | 0.787 | 9180 | 20200 | 134.7 | 30300 | 269.4 | 60600 | 70 | 2.76 | 25 | 0.98 |

| 22 | 7/8 | 22 | 0.866 | 11140 | 24500 | 163.3 | 36750 | 326.6 | 73500 | 77 | 3.03 | 27.5 | 1.08 |

DESIGN of G43 CHAIN

GRADE

- 43

FINISH

- Self Colored or Bright, Zinc Plated or Galvanized.

Strength

- 50% stronger than Gr-30 Chain.

STANDARDS

- Meets ASTM & NACM standards.

Design Factor

- 3 to 1

APPLICATION

- Trucking Industry

MATERIAL

- Carbon Steel

Our Advantages

Flexible Payment

Choose from a range of payment options to suit you such as a 30-day credit account.

Fast Delivery

Enjoy fast delivery with quick processing and timely arrivals for all your orders.

Best Rated

We Are the Highest Rated Lifting Chains Manufacturer in China With 20 Years of Experience & Knowledge

Price Match Guarantee

We are committed to offering the best prices and ensuring you never pay more than necessary.

Our Reviews

FAQ of GRADE 43 HIGH TEST CHAIN

What is Grade 43 chain?

Grade 43, also known as G43 High Test chain, is a high-strength steel chain built to handle tough tasks. It’s commonly used in industries like construction, shipping, and transportation. Whether you’re securing equipment, towing, or lifting, Grade 43 gives you the strength and reliability needed for heavy-duty work. It’s the go-to choice for businesses looking for a strong, cost-effective solution.

Grade 43 vs Grade 70 chain: what’s the difference?

Grade 43 and Grade 70 chains differ in strength and suitability for various applications. Here’s a breakdown of the key differences:

-

Strength and Durability

-

Grade 43: Lighter-duty, suitable for general cargo securing.

-

Grade 70: Heat-treated for added strength, designed for heavy-duty tasks like lifting and securing loads in high-stress environments.

-

-

Application Suitability

-

Grade 43: Ideal for medium-duty work in industries like construction and logistics.

-

Grade 70: Perfect for tasks requiring higher load-bearing capacity, such as transport and lifting heavy equipment.

-

-

Load-Bearing Capacity

-

Grade 43: Handles moderate loads and is commonly used in applications where extreme strength is not required.

-

Grade 70: Provides higher tensile strength, making it suitable for securing and lifting heavy-duty loads.

-

-

Long-Term Use

-

Grade 43: Great for tasks that don’t require frequent high-load applications.

-

Grade 70: Built for durability in heavy-duty tasks, offering a longer lifespan in extreme conditions.

-

Grade 43 Chain Rating

G43 chain refers to the specific strength grade of the chain. The “G” signifies the grade, and “43” indicates its particular tensile strength standard. This rating ensures the chain is suitable for medium-duty tasks, offering durability and reliability for general load securing and lifting tasks.

G43 Chain Strength

G43 chain is designed for medium-duty applications and can handle loads ranging from 3,000 lbs to 6,000 lbs, depending on the size. While it’s not as strong as Grade 70 or 80, it is perfect for tasks that do not require high tensile strength, such as securing lighter loads or in hoisting operations for moderate weight.

Is Grade 43 Chain DOT Approved?

Yes, Grade 43 chain is DOT-approved for use in securing loads on vehicles, such as commercial trucks or trailers. This makes it a trusted option for freight companies and logistics operators who need to comply with transportation regulations and ensure safe cargo transport.

How Can I Use Grade 43 Chain in My Business?

Grade 43 chain is commonly used in industries like construction, transportation, and rigging. You can use it to secure cargo, lift materials, or rig equipment. It is an effective choice for lighter-duty tasks where high strength is not necessary but safety and reliability are essential.

How Do I Maintain Grade 43 Chain?

Maintaining Grade 43 chain is essential to ensure its longevity and optimal performance. Here’s how you can keep it in top condition:

-

Regular Inspections

-

Check the chain for signs of wear, damage, or cracks. Inspect it before and after each use to catch any issues early.

-

-

Clean After Use

-

Clean the chain thoroughly to remove dirt, oil, and other debris that may cause wear. Use a mild cleaner that won’t damage the chain’s surface.

-

-

Lubrication

-

Apply lubricant to prevent rust and corrosion. Regular lubrication ensures smooth operation and extends the chain’s lifespan.

-

-

Proper Storage

-

Store the chain in a dry, cool place to prevent moisture exposure. Keep it off the ground and away from chemicals that could cause damage.

-

-

Replace Worn Parts

-

If you notice any stretched links, cracks, or other signs of significant wear, replace the damaged part immediately to avoid failure.

-