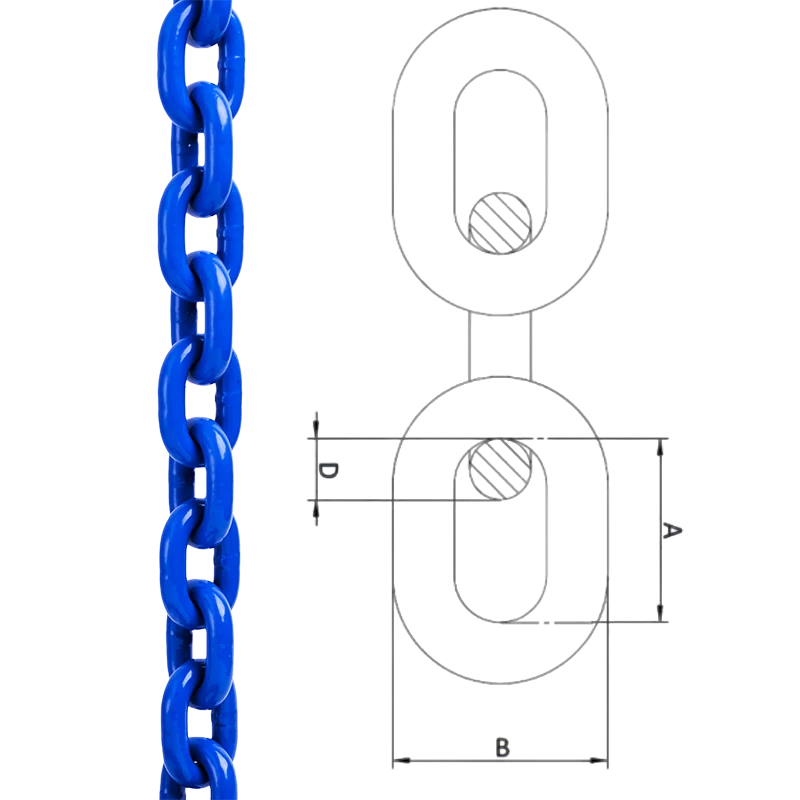

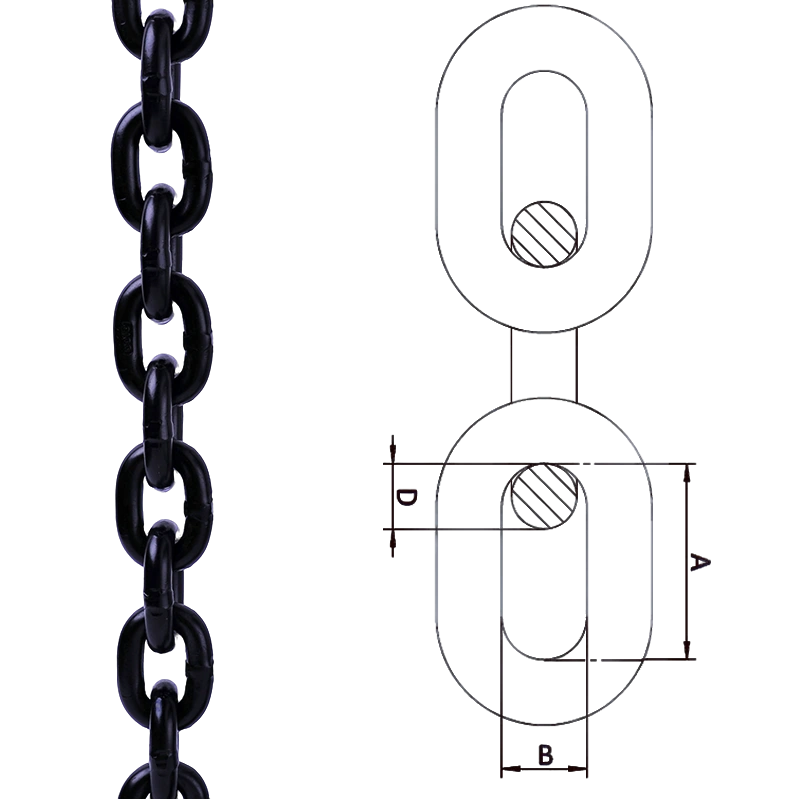

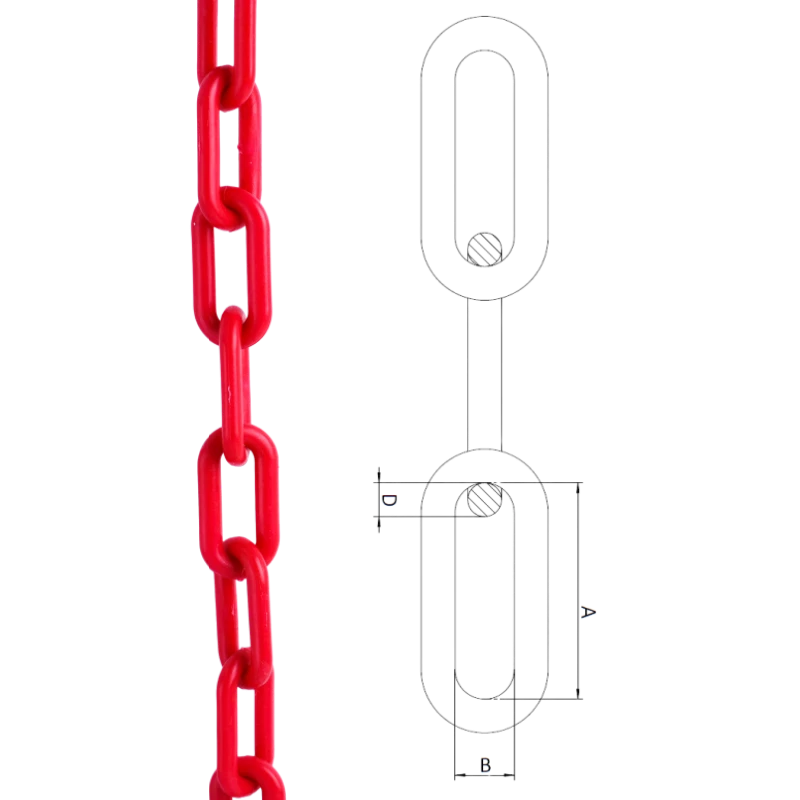

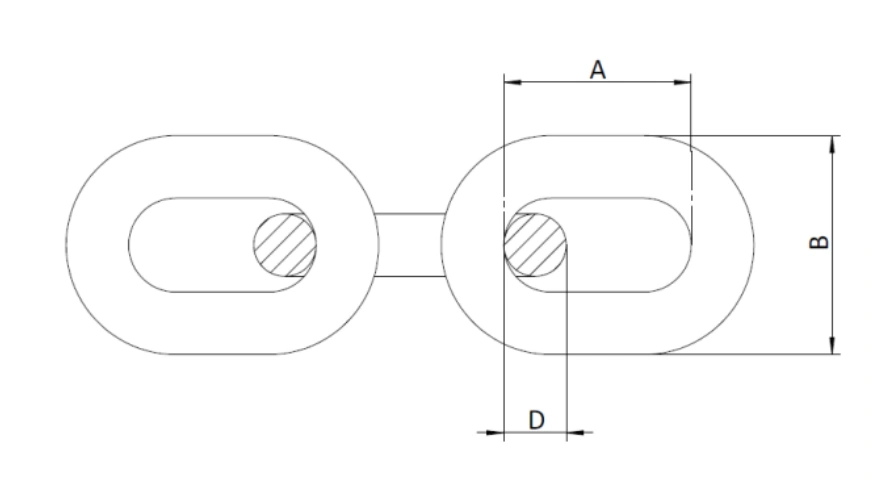

DIAGRAMS of Grade 100 Alloy Chain

GRADE 100 CHAIN SPECS

| Size mm |

Pitch mm |

Deviation Max |

Deviation Min |

Inside Width mm |

Outside Width mm |

Weight Kg/m |

Working Load Kn |

Proof Load Kn |

Break Load Kn |

| 8 | 24.00 | 24.70 | 23.30 | 10.40 | 29.60 | 1.40 | 25 | 62 | 100 |

| 10 | 30.00 | 30.90 | 29.10 | 13.00 | 37.00 | 2.20 | 39 | 98 | 157 |

| 13 | 39.00 | 40.20 | 37.80 | 16.90 | 48.10 | 3.80 | 66 | 165 | 265 |

| 16 | 48.00 | 49.40 | 46.60 | 20.80 | 59.20 | 5.70 | 100 | 251 | 402 |

| 18 | 54.00 | 55.60 | 52.40 | 23.40 | 66.60 | 7.30 | 127 | 317 | 508 |

| 20 | 60.00 | 61.80 | 58.20 | 26.00 | 74.00 | 9.00 | 157 | 392 | 628 |

| 22 | 66.00 | 68.00 | 64.00 | 28.60 | 81.40 | 10.90 | 190 | 475 | 760 |

DESIGN of G100 CHAIN

GRADE

- 100

FINISH

- Black Thermadep or Silver Shield

STANDARDS

- Meets or exceeds OSHA, Government, NACM, and ASTM specification requirements

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

APPLICATION

- Overhead Lifting/Rigging

MATERIAL

- Special analysis alloy steel

FAQ of GRADE 100 CHAIN

What is Grade 100 chain?

Grade 100 chain refers to a high-performance alloy steel lifting chain designed for demanding overhead lifting and rigging work. You use Grade 100 chain when you need higher strength with reduced chain weight compared with lower grades. Manufacturers heat-treat and alloy this chain to deliver superior tensile strength, consistent elongation control, and reliable fatigue resistance. You gain higher capacity without increasing link size, which improves handling efficiency and rigging flexibility across job sites.

Key manufacturer insights

You achieve higher lifting capacity using smaller diameters

You reduce sling weight while maintaining strength margins

You improve crane efficiency through lighter rigging systems

You support repetitive lifting cycles without strength loss

You maintain traceability through embossed grade markings

Grade 100 chain fits construction, mining, energy, heavy fabrication, port operations, and lifting equipment manufacturing where safety margins and productivity matter.

What is the Grade 100 Chain Rating?

The Grade 100 chain rating defines its mechanical performance classification under international lifting standards. You rely on this rating to confirm suitability for overhead lifting, multi-leg slings, and critical load handling. The rating reflects minimum tensile strength, controlled elongation limits, and strict heat-treatment requirements that exceed Grade 80 performance levels.

What the rating guarantees

You gain at least 25 percent higher working capacity than Grade 80

You receive predictable load behavior under dynamic lifts

You control deformation under peak stress conditions

You meet demanding safety policies across regulated industries

You support advanced rigging designs with confidence

A Grade 100 chain rating gives you measurable strength advantages without increasing system bulk.

Grade 100 Chain Working Load Limit

The Grade 100 chain working load limit defines the maximum load you can lift safely during normal service conditions. Manufacturers calculate this value using a strict design factor against minimum breaking strength. You must always size chain selection based on this limit rather than breaking strength to maintain lifting safety.

Manufacturer guidance on WLL use

You select chain diameter based on actual lift weight

You account for sling configuration and lift angle

You avoid shock loading during hoisting operations

You pair matching Grade 100 hooks and fittings

You label slings clearly to prevent misuse

Grade 100 chain offers higher WLL per size, which helps you design lighter, stronger lifting systems.

Grade 100 Chain Breaking Strength

Grade 100 chain breaking strength represents the force required to cause chain failure during controlled tensile testing. You never use this value for lifting decisions. Manufacturers establish breaking strength to verify material integrity, heat-treatment accuracy, and steel quality consistency.

Why breaking strength matters to you

You gain confidence in material durability

You verify compliance with global lifting standards

You assess safety margins during engineering review

You validate supplier manufacturing quality

You confirm resistance to overload scenarios

Breaking strength supports engineering validation while the working load limit governs real lifting use.

Grade 100 Chain Components

Grade 100 chain requires matched Grade 100 components to maintain system integrity. You must use hooks, connectors, shortening devices, and master links rated specifically for Grade 100 service. Mixing grades reduces capacity and increases risk.

Approved component pairing

Grade 100 clevis sling hooks

Grade 100 master links and sub-assemblies

Grade 100 shortening clutches

Grade 100 mechanical connectors

Grade 100 coupling links

Grade 80 vs Grade 100 Chain: Which Should You Choose?

Your choice depends on load requirements, handling efficiency, and long-term operational goals. Grade 80 chain fits general lifting needs. Grade 100 chain supports high-capacity lifts where weight reduction and strength matter most.

Decision factors to evaluate

You compare load weight and lift frequency

You consider crane capacity optimization

You assess worker fatigue from rigging weight

You plan for future lifting upgrades

You evaluate lifecycle cost rather than unit price