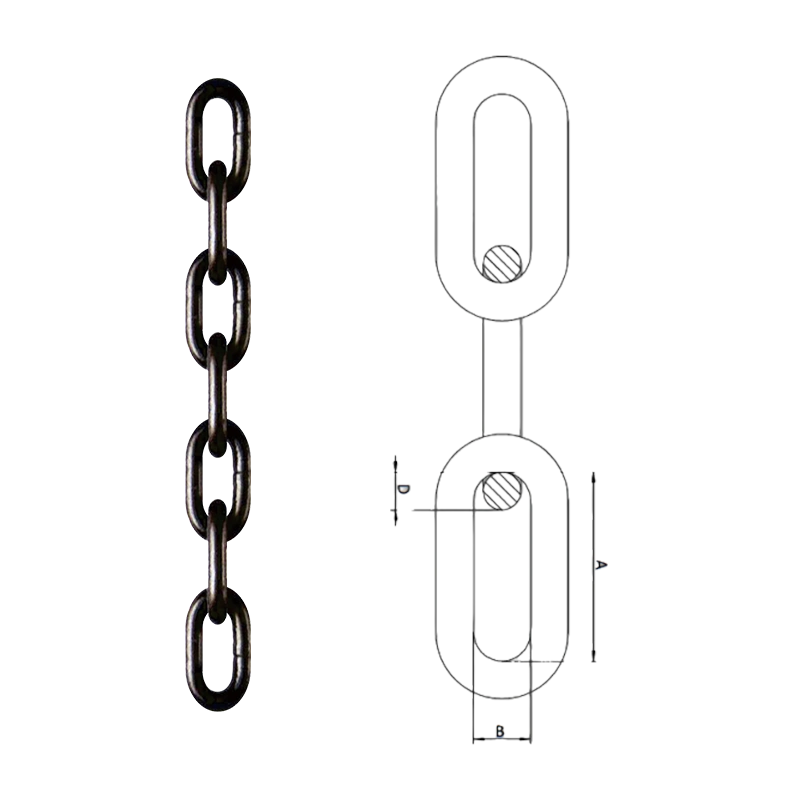

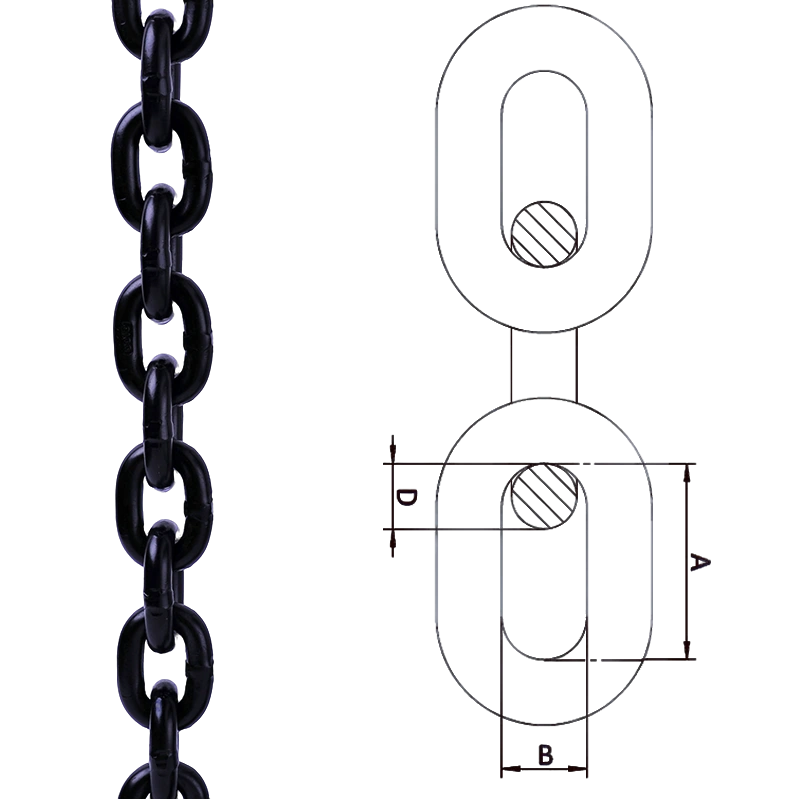

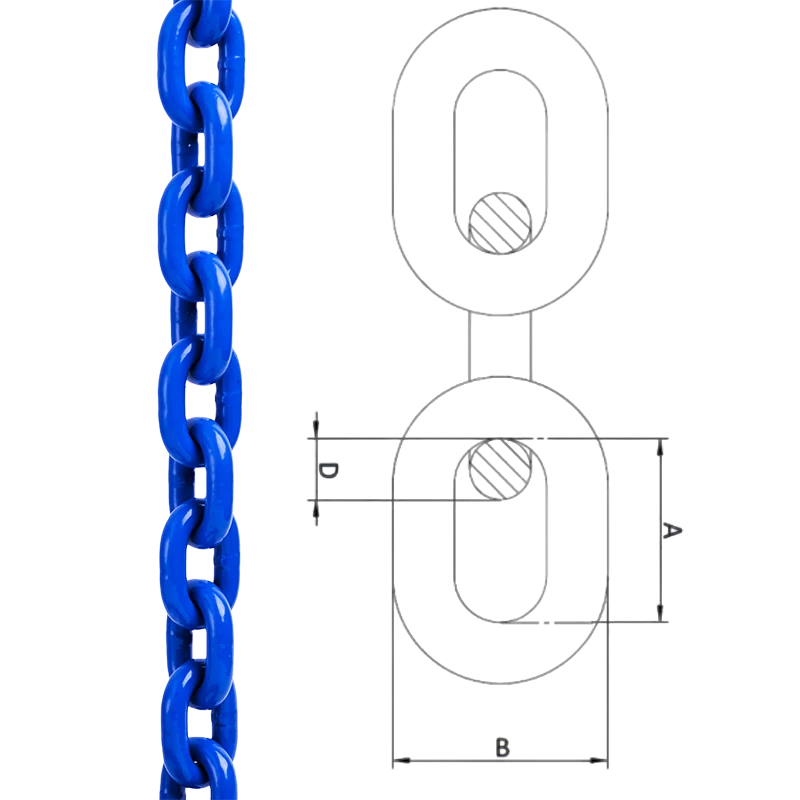

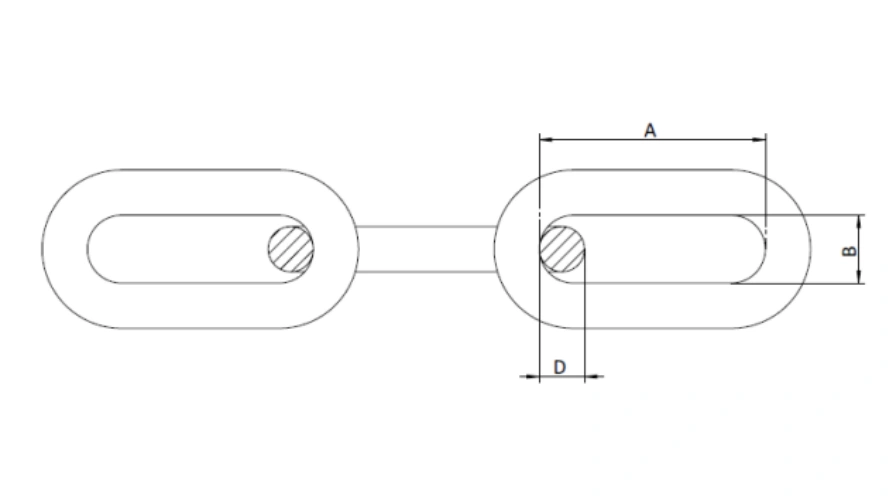

DIAGRAMS of G80 Chain

Grade 80 Chain Specs

| SIZE | A | B | MBL | WEIGHT |

| MM | MM | MM | TON | KG/M |

| 9 | 57 | 16 | 10.2 | 1.5 |

| 11 | 66 | 18 | 15.4 | 2.1 |

| 13 | 80 | 23 | 21.4 | 3 |

| 16 | 100 | 26 | 32 | 4.4 |

| 19 | 100 | 28 | 45 | 6.5 |

| 20 | 100 | 30 | 50 | 7.3 |

| 22 | 120 | 32 | 60 | 8.5 |

DESIGN of GRADE 80 CHAINS

GRADE

- 80

FINISH

- Black Thermadep

STANDARDS

- Meets or exceeds OSHA, Government, NACM, and ASTM specification requirements

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

APPLICATION

- Overhead Lifting

MATERIAL

- Special analysis alloy steel

FAQ of G80 Chains

What is Grade 80 chain?

Grade 80 chain is a heat-treated alloy steel lifting chain designed for overhead lifting and critical load handling. You choose Grade 80 chain when lifts demand strength, durability, and controlled elongation. This chain grade supports cranes, hoists, and chain slings across heavy industries. Manufacturing control over alloy composition and heat treatment gives you predictable working load limits and repeatable performance. You gain confidence because each link handles stress without distortion during real lifting cycles.

What defines Grade 80 chain

-

Alloy steel construction

-

Heat-treated strength

-

Overhead lifting approval

-

Marked grade identification

-

Controlled elongation behavior

Grade 80 Chain Working Load Limit

The working load limit defines the maximum load Grade 80 chain can handle during normal lifting operations. You rely on this value to plan safe lifts and protect equipment and crews. Manufacturers calculate working load limits based on material strength, link size, and safety margins. You must match chain size to total load weight and sling configuration to stay within rated limits. Exceeding limits increases risk and shortens chain life.

What affects working load limit

-

Chain diameter

-

Sling angle

-

Number of legs

-

Load movement

-

Shock loading

What is the G80 chain rating?

The G80 chain rating identifies the chain as Grade 80 lifting chain suitable for overhead use. You read this rating on stamped markings that show grade and size. The rating confirms that the chain meets strength and performance requirements for lifting operations. Manufacturers proof test and break test chains to ensure rating accuracy. You depend on this rating to align chain performance with hoists and fittings.

What the rating tells you

-

Approved lifting grade

-

Compatible fittings

-

Rated working load

-

Traceable production

-

Safety compliance

How strong is Grade 80 chain?

Grade 80 chain delivers high tensile strength with controlled flexibility. You lift heavier loads using smaller chain sizes compared to lower grades. Manufacturing precision ensures each link shares load evenly during lifting. Strength consistency matters because uneven performance causes premature failure. You gain long service life when strength stays uniform across the chain length.

Strength characteristics

-

High tensile capacity

-

Stable elongation

-

Strong fatigue resistance

-

Reliable shock handling

-

Uniform link performance

Grade 70 vs Grade 80 chain: what is the difference?

Grade 70 chain serves load binding and transport tasks. Grade 80 chain supports overhead lifting. You must never replace Grade 80 chain with Grade 70 chain for lifting because Grade 70 lacks required strength and testing. Manufacturing standards separate these grades by material and heat treatment. Choosing the correct grade protects safety and compliance.

-

Grade 70 for tie-down use

-

Grade 80 for lifting use

-

Higher strength in Grade 80

-

Different markings

-

Different safety expectations

Grade 80 vs Grade 100 Chain: How Do They Compare?

Grade 100 chain offers higher strength than Grade 80 chain at the same size. You select Grade 100 when weight reduction or higher capacity matters. Grade 80 remains widely used due to cost efficiency and broad compatibility. Manufacturers support both grades to match different lifting strategies.

-

Higher capacity in Grade 100

-

Broader availability in Grade 80

-

Compatible fittings differ

-

Cost varies by grade

-

Application choice drives selection

How do you select the right Grade 80 chain size?

Chain size selection requires accurate load calculation and sling geometry review. You must consider total load weight and lifting angles. Manufacturers provide load charts so you match diameter to real conditions. Incorrect sizing creates excess stress and shortens chain life.

Selection criteria

-

Total load weight

-

Sling angle

-

Lift frequency

-

Environmental exposure

-

Equipment compatibility

How should Grade 80 chain be inspected?

Inspection keeps lifting operations safe and predictable. You inspect Grade 80 chain before use and during service. Visual checks reveal wear, cracks, and elongation. Manufacturer markings help verify grade and size during inspections. Immediate removal prevents accidents.

Inspection focus

-

Link deformation

-

Surface cracks

-

Excessive wear

-

Heat discoloration

-

Missing markings