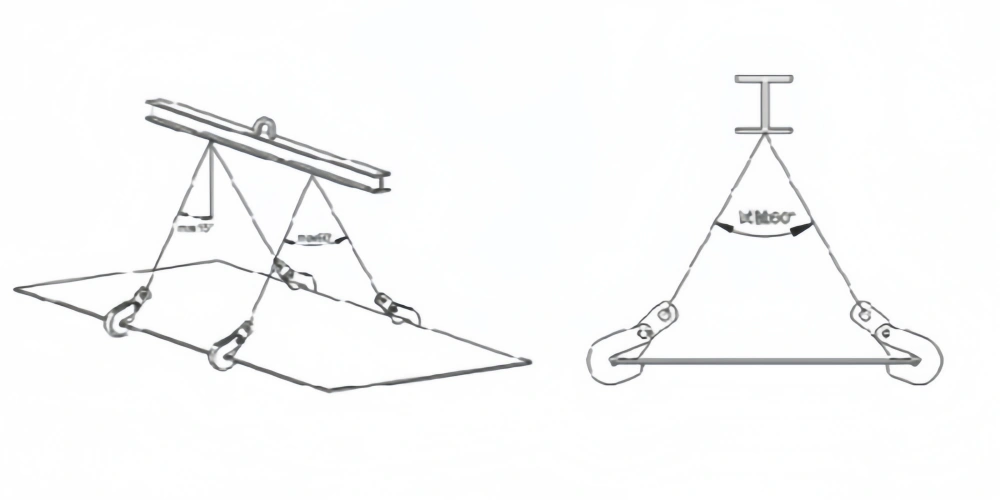

HORIZONTAL LIFTING CLAMP DRAWING

HORIZONTAL PLATE LIFTING CLAMP SPECIFICATIONS

| Model | WLL (tons)per pair | Jaw Opening(mm) | Weight(kg) |

| L0.8 | 0.8 | 0-15 | 1.6 |

| L1 | 1.0 | 0-20 | 4.3 |

| L1.6 | 1.6 | 0-25 | 8.4 |

| L2 | 2.0 | 0-30 | 7.8 |

| L2.5 | 2.5 | 0-40 | 11 |

| L2.5(B) | 2.5 | 25-50 | 12.5 |

| L3.2 | 3.2 | 0-40 | 12.5 |

| L3.2(B) | 3.2 | 30-60 | 11.6 |

| L5 | 5.0 | 0-50/10-60 | 20 |

| L5(B) | 5.0 | 50-80 | 21 |

HORIZONTAL LIFTING CLAMPS INFORMATION

-

Working Load Limit (WLL):

-

The working load limit ranges from 0.8 to 5 tons.

-

This defines the maximum weight the horizontal lifting clamp can safely support when used in pairs or multiples, with a 60-degree lifting angle.

-

-

Applications:

-

Suitable for horizontal lifting of steel plates, construction materials, and profiled bars.

-

Ideal for industries that require reliable, efficient lifting of heavy, flat materials in horizontal positions.

-

-

Material & Construction:

-

Made from high-quality low-carbon alloy steel for enhanced strength and durability.

-

The main body and components are die-forged from special alloy steels, optimally tempered to ensure maximum strength and long-lasting performance.

-

-

Handling Precautions:

-

Avoid snatch or shock loading to prevent damage during operation.

-

Ensure the clamp is used in pairs or multiples with the correct lifting angle for maximum safety and load capacity.

-

Always ensure that the clamp doesn’t come into contact with the lifted object during the operation.

-

INSTRUCTIONS & CAUTIONS

Always Use in Pairs or Multiples

The horizontal lifting clamp is designed to be used in pairs or even multiples for optimal load support. The working load limit (WLL) is based on using two clamps with a 60-degree lifting angle. Never use a single clamp for lifting large loads, as this could compromise safety. For larger or heavier materials, consider using four clamps to evenly distribute the load.

Ensure Proper Alignment

Before lifting, make sure the clamp is securely attached and properly aligned with the material. Incorrect placement can cause the clamp to slip or not fully engage, potentially leading to accidents. Always double-check the positioning of the clamp under the load to ensure it is tightly secured and that the material is stable before proceeding with the lift.

Avoid Snatch or Shock Loading

Never allow snatch or shock loading during lifting. This means you should not abruptly jerk the load or apply sudden force. Snatch loading can damage the clamp and the material, and it may result in accidents. Always lift the material in a smooth, controlled manner to ensure the clamp’s integrity and the safety of your workers.

Regularly Inspect and Maintain the Clamp

Before every use, inspect the clamp for any signs of wear, damage, or corrosion. A worn-out clamp can lead to failure during lifting. Make sure the locking mechanism works properly, and that all components are free from cracks or damage. Lubricate the moving parts to ensure smooth operation, and clean it after each job to maintain its durability.

OUR ADVANTAGES

Customizable to Your Needs

At Powerful Machinery, we understand that every business has unique requirements. That’s why we offer custom-engineered solutions to meet your specific needs. Whether it’s product modifications, special configurations, or unique features, we tailor our products to help you optimize your operations and stay ahead in the market.

One-Stop Sourcing for Convenience

We offer a one-stop sourcing solution to make your ordering process simple and efficient. From lifting equipment to custom options, we provide everything under one roof. You won’t need to work with multiple suppliers – everything you need is available with just one contact, saving you time and hassle while ensuring consistent quality across all products.

Top-Tier Quality and Safety Standards

At Powerful Machinery, we prioritize quality and safety. All our products are rigorously tested to meet the highest industry standards. With full certifications and continuous quality checks, you can be confident that every item you purchase is durable, reliable, and built to perform. We ensure your operations run smoothly and safely, every time.

Efficient Logistics and On-Time Delivery

We pride ourselves on offering efficient logistics and timely delivery. No matter the size of your order, we ensure that everything arrives when you need it, with no delays. Our streamlined transportation process guarantees that you receive your products on time, so you can keep your projects moving forward without unnecessary waiting.

FAQ

How do I ensure the horizontal lifting clamp is securely attached?

Before lifting, double-check that the clamp is properly aligned under the material. Ensure that the lock mechanism is fully engaged, and the clamp’s jaw width fits the material securely. Always test the clamp’s grip before starting the lift to ensure it is stable and safe to use.

Can I use the horizontal lifting clamp with other lifting equipment?

Yes, the horizontal lifting clamp is designed to work with forklifts, cranes, and other lifting equipment, provided it is used in the correct manner. Always ensure that the clamp is compatible with the lifting machinery and is used according to the manufacturer’s instructions for safety.

What is the best way to transport a horizontal lifting clamp?

Store and transport the horizontal lifting clamp in a safe, dry area to prevent rust and corrosion. If transporting over long distances, ensure the clamp is securely packaged to avoid damage during handling. Always handle the clamp with care to preserve its strength and functionality.

How do I calculate the total lifting capacity with multiple clamps?

-

Identify the working load limit (WLL) of each horizontal lifting clamp.

-

Multiply the WLL of each clamp by the number of clamps you plan to use.

-

For example: If each clamp supports 2 tons and you’re using two clamps, the total lifting capacity is 4 tons.

-

-

Ensure the load is evenly distributed across all clamps to prevent strain on both the clamps and lifting equipment.

-

Confirm that the lifting points are at the correct angle for maximum load distribution.

How do I order a horizontal lifting clamp from Powerful Machinery?

Ordering is easy! You can place your order directly through our website or contact our sales team for assistance. We offer bulk pricing and customization options to meet your specific needs. Our team is always available to help you with product details, pricing, and delivery options.