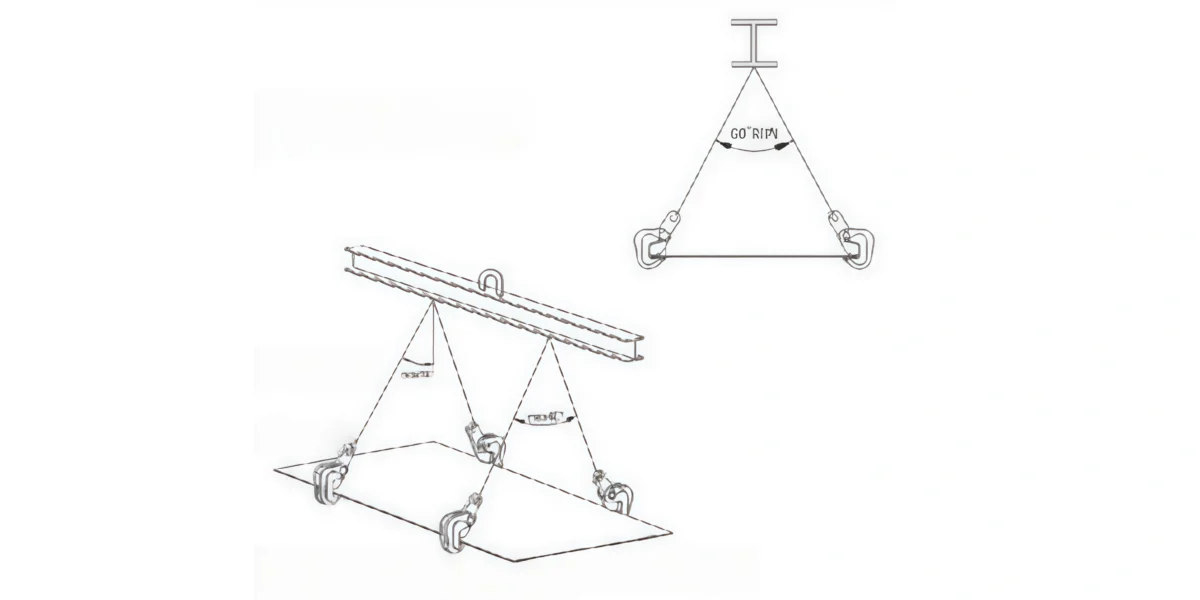

HORIZONTAL PLATE LIFTING CLAMPS DRAWING

SPECIFICATIONS of HORIZONTAL PLATE CLAMP FOR LIFTING

| Model | WLL (tons)per pair | Jaw Opening(mm) | Weight(kg) |

| LA1 | 1.0 | 0-30 | 3.7 |

| LA2 | 2.0 | 0-50 | 5.2 |

| LA3.2 | 3.2 | 0-60 | 7.7 |

| LA5 | 5.0 | 10-60 | 12.5 |

| LA6 | 6.0 | 10-100 | 15 |

| LA10 | 10.0 | 20-120 | 26.6 |

HORIZONTAL STEEL PLATE LIFTING CLAMP INFORMATION

-

Working Load Limit (WLL):

The horizontal plate lifting clamp has a working load limit (WLL) ranging from 1 to 10 tons, ensuring versatility for different lifting tasks. -

Material Handling:

Suitable for lifting and transporting steel plates, construction materials, and profiled bars in a horizontal position, making it ideal for industries like construction, steel manufacturing, and warehousing. -

Construction:

Made from high-quality carbon steel, this clamp ensures durability and long-lasting performance even in heavy-duty lifting operations. -

Safety & Usage:

The clamp is designed for use in pairs or multiples, with a 60-degree lifting angle. It is not recommended for shock loading to maintain safety during lifting operations. -

Application Flexibility:

The clamp can be used in a variety of applications, from lifting steel plates to construction profiles, making it a versatile solution for different industries.

INSTRUCTIONS & CAUTIONS

Ensure Proper Load Capacity

Before using the horizontal plate lifting clamp, make sure the working load limit (WLL) is not exceeded. The clamp is designed for loads between 1-10 tons, so always check the weight of the material you’re lifting and ensure it matches the clamp’s capacity. Using the clamp beyond its rated capacity could lead to dangerous accidents.

Use in Pairs or Multiples for Safety

The clamp should always be used in pairs or multiples when lifting heavy materials. Using only one clamp can cause uneven distribution of weight, increasing the risk of accidents or damage to both the equipment and the load. Always lift steel plates and profiled bars with at least two clamps, and ensure they are correctly positioned.

Avoid Shock or Snatch Loading

When lifting, avoid shock loading or snatch loading. These sudden movements or impacts can cause significant damage to the clamp and the material being lifted. Always lift slowly and steadily, ensuring that the load is evenly distributed. If you need to move the load quickly, consider using additional equipment to stabilize it.

Regular Inspection and Maintenance

To ensure the clamp continues to perform at its best, conduct regular inspections and maintenance. Check for signs of wear, rust, or damage before each use. Clean the clamp after each lifting operation to remove any debris or dirt that could affect its performance. Also, ensure that the locking mechanism is functioning properly for secure lifting.

OUR ADVANTAGES

Customized Solutions for Your Business

At Powerful Machinery, we understand that every business has unique needs. We offer custom-engineered solutions tailored to fit your specific requirements. Whether it’s adapting products or providing specialized features, we ensure that our solutions meet the exact demands of your operations, helping you improve efficiency and productivity.

Competitive Pricing with High-Quality Standards

We offer competitive pricing without compromising on quality. Unlike other manufacturers, we use premium materials and maintain strict quality control processes to ensure durability and performance. Our goal is to deliver cost-effective solutions that help your business thrive while ensuring long-lasting, reliable equipment.

Efficient After-Sales Support and Service

Our commitment doesn’t end with the sale. At Powerful Machinery, we provide comprehensive after-sales support, including product maintenance, troubleshooting, and repairs. Our dedicated customer service team is always available to assist with any concerns or issues, ensuring minimal downtime and maximum productivity for your business.

Fast Delivery and Efficient Logistics

We prioritize efficient logistics to ensure that your orders are delivered quickly and safely. With our global network and optimized supply chain, we can guarantee on-time deliveries, reducing waiting times for your business. Whether you’re ordering in bulk or requiring urgent supplies, we’ve got you covered with fast and reliable delivery options.

FAQ

How do I use a horizontal plate lifting clamp?

-

Attach to Lifting Equipment

Begin by attaching the horizontal plate lifting clamp to your lifting equipment, such as a forklift or hoist. -

Adjust the Clamp

Adjust the clamp’s jaws to securely grip the material. Make sure the clamp is positioned properly and tightly locked around the steel plate or construction material. -

Lift the Material

Once the clamp is securely in place, carefully lift the material. Ensure smooth, controlled movement. -

Move Horizontally to Desired Location

After lifting, move the material horizontally to its desired position. -

Check Lock Mechanism

Always double-check the locking mechanism before lifting to ensure the clamp is securely engaged for safety.

What should I do if the horizontal plate lifting clamp is damaged?

If you notice any signs of damage or wear on the clamp, it’s important to stop using it immediately. Inspect the damaged parts and contact our customer support team for assistance with repairs or replacement. Regular maintenance helps prevent such issues, ensuring long-lasting use.

What should I do if the material I’m lifting is irregularly shaped?

If you’re lifting materials with irregular shapes, consider using a specialized lifting clamp or adjust the jaw width on your horizontal plate lifting clamp to better fit the material. If the material is not securely held, it may shift during the lifting process, which could be dangerous. Always ensure a tight grip and even load distribution.

How do I order a horizontal plate lifting clamp?

Ordering a horizontal plate lifting clamp is simple. You can place an order directly through our website or contact our sales team for bulk pricing and customization. Let us know your specific requirements, and we’ll ensure that you receive the right clamp for your needs. Feel free to reach out to us for more details or assistance with your order.