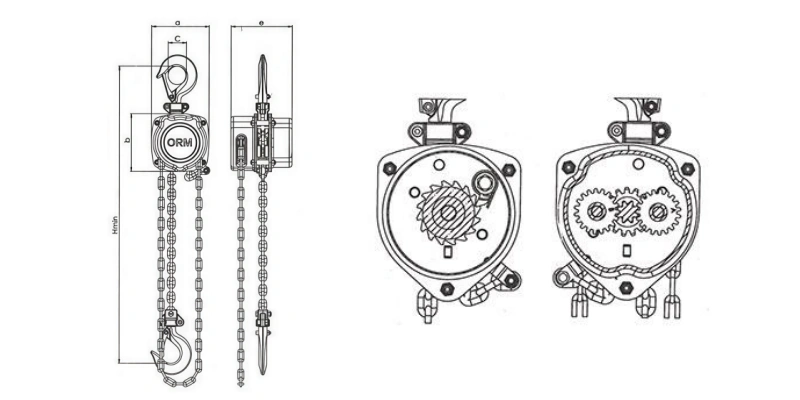

HAND OPERATED CHAIN PULLEY BLOCK DRAWING

MANUAL CHAIN PULLEY BLOCK SPECIFICATIONS

| Model | ORM-250KG | ORM-500KG | ORM-1000KG | ORM-2000KG | ORM-3000KG | ORM-5000KG | ORM-10000KG |

| Capacity(t) | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 |

| Standard lift(m) | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Test load(t) | 0.375 | 0.75 | 1.5 | 3 | 4.5 | 7.5 | 15 |

| Min distance between hooks(mm) | 285 | 315 | 340 | 380 | 475 | 600 | 700 |

| Chainpull to lift full load(n) | 25 | 33 | 34 | 34 | 35 | 39 | 41 |

| No. of load chain fall lines | 1 | 1 | 1 | 1 | 2 | 2 | 4 |

| Diameter of load chain(mm) | 4×12 | 5×15 | 6×18 | 8×24 | 10×30 | 10×30 | 10×30 |

| Net weight(kg) | 4.2 | 5.7 | 10.8 | 17.1 | 26.2 | 40 | 73.2 |

| Gross Weight(kg) | 5 | 6.5 | 12.5 | 19 | 28 | 43 | 76 |

| Packing measurement L×W×H(cm) | 18×12×10 | 19×16×11 | 26×17×18 | 30×17×22 | 35×17×26 | 44×32×17 | 62×50×26 |

FEATURES OF MANUAL HOIST CHAIN PULLEY BLOCK

-

Capacity: Ranges from 0.25t to 10t, providing flexibility for a wide range of lifting applications.

-

Heavy-duty & compact design: Meets all relevant global standards, ensuring durability and reliability in tough conditions.

-

Reliable braking system: Equipped with a reliable disc brake for enhanced safety and control during lifting operations.

-

Premium-grade load chain: Made from high-quality alloy for strength and long-lasting performance.

-

Zinc-plated hand chain: Provides resistance to corrosion, ensuring smooth operation over time.

-

Drop-forged hooks: Heat-treated for superior strength and wear resistance, ensuring safe lifting.

-

CE & GS certified: Complies with international safety and quality standards, giving you confidence in its performance.

INSTRUCTIONS & CAUTIONS

Proper Installation is Key

Before using the manual chain pulley block, ensure it’s securely mounted to a strong, stable structure. Proper installation is essential for safety and effective operation. Make sure the hoist is free from any obstructions, and that the support point can handle the load. Incorrect mounting can lead to accidents or damage to both the hoist and the load.

Avoid Overloading the Hoist

Never exceed the hoist’s rated load capacity. Overloading can lead to equipment failure, damage, or even accidents. Always verify the weight of the load you plan to lift and compare it with the hoist’s maximum capacity. It’s important to use a load scale if needed to avoid the risks associated with overloading, ensuring long-term safety and performance.

Operate Smoothly and Evenly

When lifting or lowering a load, operate the chain block smoothly. Pull the hand chain steadily without jerking or rushing the process. Abrupt movements can damage internal components, affect the hoist’s performance, and shorten its lifespan. For best results, always aim for smooth, consistent operation to reduce strain on both the hoist and the load.

Regular Maintenance and Inspection

Keep your manual chain pulley block in top condition by inspecting it regularly. Before each use, check the chain, hooks, and braking system for signs of wear. Ensure the chain is properly lubricated and free from rust, and that the hooks function correctly. Regular maintenance and prompt repairs help extend the hoist’s lifespan and ensure its safety during operations.

OUR ADVANTAGES

Custom-Engineered Solutions for Your Business

No two businesses are the same, and we recognize that. That’s why we offer tailored, custom-engineered solutions to meet your specific lifting needs. Whether you need specialized load capacities or unique features, we work closely with you to deliver products that enhance your performance and productivity.

Streamlined One-Stop Sourcing

We simplify your purchasing process by offering a complete range of lifting equipment under one roof. With Powerful Machinery, you can source everything you need in one place—saving you time and effort. This convenient service helps reduce the complexity of working with multiple suppliers, allowing you to focus on your core business.

Efficient Logistics and On-Time Delivery

We know how important it is to get your orders when you need them. Powerful Machinery ensures fast and reliable delivery through our trusted logistics network. With us, you can count on timely arrivals, helping you avoid delays and keep your operations on track.

Customer Support and After-Sales Service

At Powerful Machinery, we’re committed to your success long after the sale. Our expert after-sales team is always ready to help with technical support, maintenance advice, and repairs. We understand that uptime is critical, so we ensure any issues are addressed quickly, keeping your operations running smoothly and efficiently.

FAQ

What is a manual chain pulley block used for?

A manual chain pulley block is a reliable lifting device used to move heavy loads in environments like factories, construction sites, and warehouses. It’s especially useful where no power supply is available. This hoist can handle various lifting tasks, including loading/unloading equipment and goods, offering a simple, cost-effective solution for overhead lifting operations.

How do you operate a manual chain pulley block?

-

Step 1: Attach the Load

Securely attach the load to the hook and ensure it’s balanced. Make sure the load is properly positioned before lifting. -

Step 2: Mount on Stable Support

Ensure the hoist is mounted on a stable, secure structure to prevent instability during operation. -

Step 3: Lift the Load

Pull the hand chain steadily to lift the load. Avoid jerking the chain to ensure smooth operation. -

Step 4: Lower the Load

To lower the load, release the chain slowly and carefully. Ensure control at all times. -

Step 5: Maintain Balance

Always ensure the load is balanced to avoid damaging the hoist or causing accidents. Smooth, controlled movements are essential.

How do I choose the right manual chain pulley block for my needs?

-

Step 1: Check Load Capacity

Ensure the hoist’s load capacity exceeds the weight of the load you’ll be lifting. Always factor in a margin for safety. -

Step 2: Consider the Lifting Height

Make sure the hoist provides the required lifting height for your operation. Measure the distance to ensure it meets your specific needs. -

Step 3: Evaluate the Environment

Consider where the hoist will be used. If it’s for outdoor use or in humid environments, look for models with corrosion-resistant features to ensure durability. -

Step 4: Match the Hoist to Your Application

Think about the type of work you’ll be doing. Different tasks may require specific features such as adjustable hooks or safety mechanisms.

How do I maintain a manual chain pulley block?

-

Step 1: Inspect Regularly

Check the chain and hooks for signs of wear, rust, or damage. Look for any cracks or deformations to ensure safe operation. -

Step 2: Lubricate the Chain

Lubricate the chain regularly to ensure smooth operation and to prevent corrosion, which helps extend the hoist’s lifespan. -

Step 3: Clean After Each Use

Clean the hoist after every use to remove dirt, debris, or any contaminants that could affect its performance. -

Step 4: Store Properly

When not in use, store the hoist in a dry, clean area to prevent rust and damage. Avoid leaving it in damp or harsh conditions.

How do I troubleshoot common problems with a manual chain pulley block?

-

Step 1: Check for Visible Wear

Inspect the chain and hooks for any signs of wear, rust, or damage. Worn components can cause the hoist to malfunction. -

Step 2: Verify Load Capacity

Ensure the hoist is not overloaded. Exceeding the rated load capacity can lead to failure or damage to the hoist. -

Step 3: Inspect the Brake System

Check that the brake system is functioning correctly. A faulty brake can result in load slippage or unsafe operation. -

Step 4: Examine the Hand Chain

If the hoist isn’t lifting properly, inspect the hand chain for any obstructions or damage. Ensure it moves smoothly without resistance. -

Step 5: Perform Regular Maintenance

Regular cleaning, lubrication, and inspection help prevent most issues. Follow the manufacturer’s guidelines for optimal upkeep.