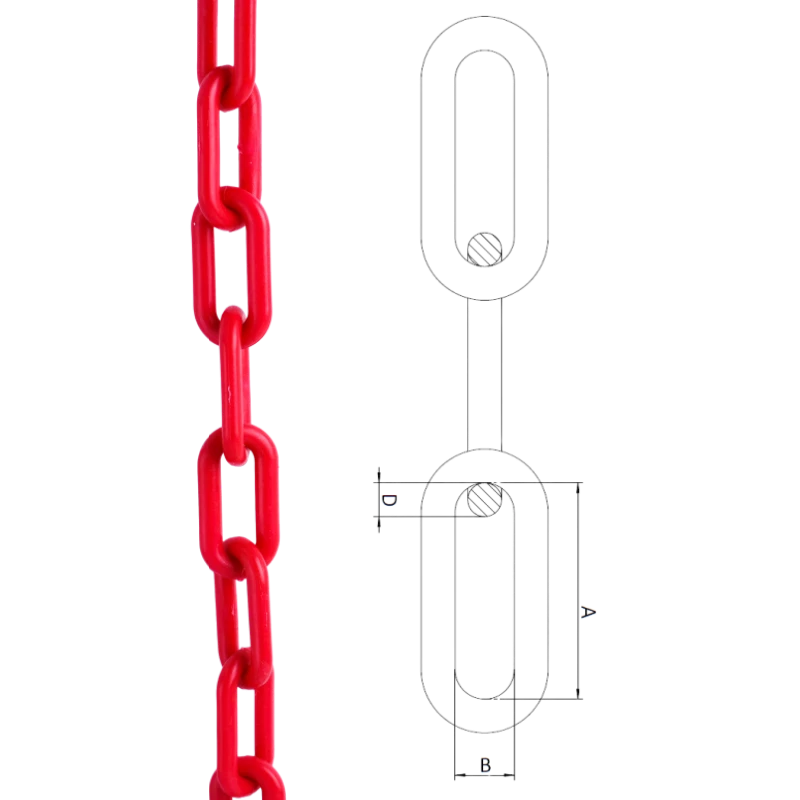

DIAGRAM of PLASTIC CHAINS

SPECIFICATIONS of PLASTIC CHAIN LINKS

| SIZE | INNER LENGTHA(MM) | OUTER WIDTHB(MM) | WEIGHT KG/M | SECTION |

| 2 | 10 | 7 | 0.009 | ROUND |

| 3 | 13 | 11 | 0.02 | ROUND |

| 4 | 19 | 16 | 0.03 | ROUND |

| 6 | 25 | 22 | 0.065 | ROUND |

| 27 | 20 | 0.06 | FLAT | |

| 8 | 38 | 27 | 0.11 | FLAT |

| 34 | 25 | 0.09 | FLAT | |

| 10 | 50 | 38 | 0.2 | ROUND |

| 12 | 67 | 40 | 0.285 | ROUND |

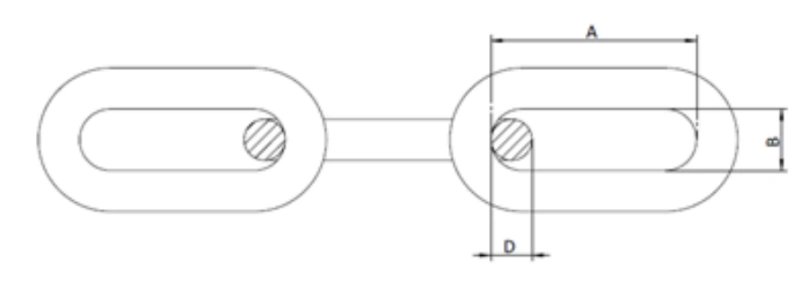

DESIGN of PLASTIC CHAIN LINK

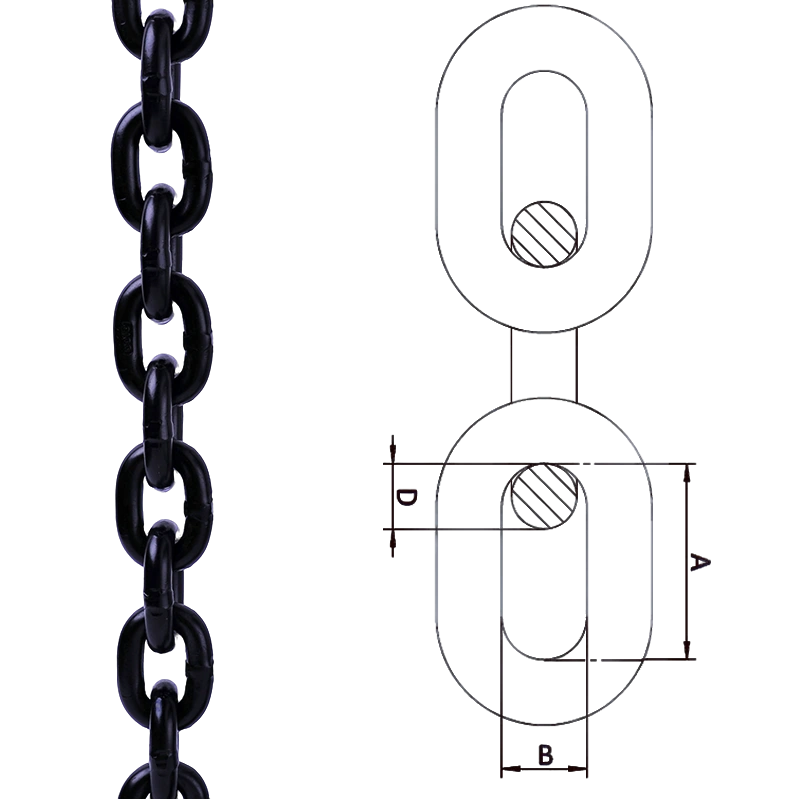

FEATURES

- Rustproof

- No sharp edges

- Lightweight

- Washable

- Non-magnetic

- Non-conductive

- Abrasion-resistant

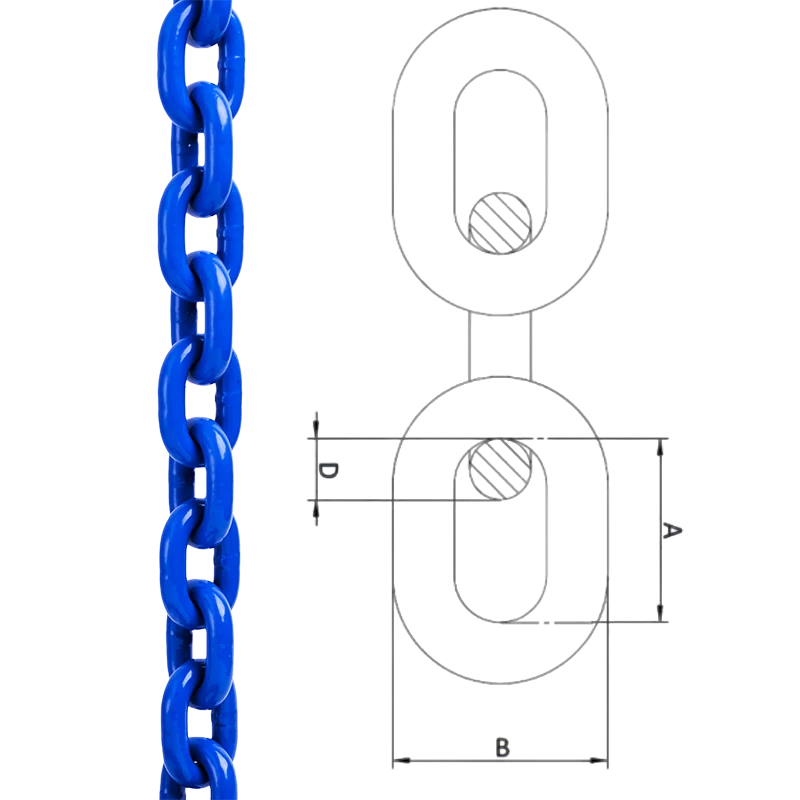

APPLICATION

- Crowd Control

- Industrial Use

- Decorative Applications

OUR ADVANTAGES

Tailored Customization

We provide custom plastic chains to fit your specific needs. Whether it’s size, material, finish, or strength grade, we’ve got you covered. This flexibility makes our chains ideal for everything from industrial to agricultural and marine applications.

Built to Last

Our plastic chains are crafted from durable materials like HDPE and PVC, built to withstand tough environments.

Industry-Approved

All our chains are made to meet relevant certifications, so you can trust their safety and reliability. We ensure that every chain performs to the highest specifications, keeping you compliant with industry regulations.

Great Value with Bulk Discounts

Get the best value for your money with our competitive pricing and bulk discounts for large orders. We make sure you get a great deal without compromising on the quality of our plastic chains.

FAQ of PLASTIC LINK CHAIN

How strong is plastic chain?

Plastic chains are designed to handle moderate to heavy-duty applications, depending on the material. Made from durable plastics like HDPE and PVC, they can withstand significant tension and weight. While not suited for heavy lifting, they provide excellent strength for securing areas, marking hazardous zones, and crowd control. They resist wear, UV degradation, and are abrasion-resistant, ensuring long-term reliability.

Are plastic chains safe for industrial use?

Yes, our plastic chains are perfectly suited for industrial environments. They are non-conductive, meaning they won’t transmit electricity, making them safe for use near electrical equipment. Additionally, they’re resistant to chemicals and weathering, ensuring they remain safe and reliable even in harsh industrial conditions, from factories to warehouses. Their durability ensures consistent performance without risk.

Can plastic chains withstand extreme weather conditions?

Absolutely! Plastic chains are highly resistant to both UV rays and the elements. With materials like HDPE and PVC, they remain functional in all kinds of weather, including rain, snow, and intense sunlight. Their UV resistance prevents them from becoming brittle or discolored, making them ideal for outdoor use in areas like construction sites, parking lots, or for crowd control in any climate.

How to cut plastic chain?

Cutting plastic chain looks simple, yet improper cutting creates sharp edges, cracked links, or weakened connection points. You should cut plastic chain based on link thickness, material hardness, and intended reuse. As a manufacturer, we design links to allow clean cuts when you use the right method.

Best practices you should follow include:

-

Measure chain length under slight tension to avoid miscounting links

-

Use heavy-duty bolt cutters for thick polyethylene links

-

Use a fine-tooth saw for clean cuts on display or retail setups

-

Cut through the center of the link, not near the weld line

-

Smooth cut edges with light sanding for hand-contact areas

-

Test the cut end under light pull before installation

Are plastic chains load-bearing?

Plastic chains are designed for non-load-bearing applications. While they offer excellent strength for securing areas and marking hazards, they are not intended for lifting heavy loads. They are perfect for blocking off zones, directing traffic, or controlling crowds, but for lifting applications, you should use appropriate lifting chains made from steel or other load-bearing materials.

What should you know about colored plastic chain before choosing it?

Colored plastic chain does more than mark off space. You use color to control behavior, improve visibility, and support branding. As a manufacturer, we design colored plastic chain to balance strength, color stability, and outdoor performance, not just appearance. You should match color choice to environment, user interaction, and exposure conditions.

Key points you should evaluate include:

-

Color meaning for your application such as red for restricted access or yellow for caution zones

-

UV resistance level that keeps color bright under long-term sunlight

-

Pigment integration that runs through the entire link instead of surface coating

-

Contrast visibility against floors, pavement, or water

-

Color consistency across production batches for large projects

-

Compatibility with matching plastic posts or stanchions

How do you choose the right plastic chain size for your application?

Choosing plastic chain size requires you to think about environment, contact frequency, and visual communication. As a manufacturer, we see most sizing errors happen when buyers underestimate daily handling and exposure conditions. Size should support both performance and perception.

You should base your choice on:

-

Human interaction level such as hand pulling or leaning

-

Installation height and viewing distance

-

Indoor or outdoor exposure conditions

-

Frequency of removal and reinstallation

-

Matching size with posts, hooks, or cones

-

Balance between visibility and portability

Right-sized plastic chain reduces replacement costs and improves safety clarity. You gain better control and cleaner installations when size matches real-world use instead of assumptions.