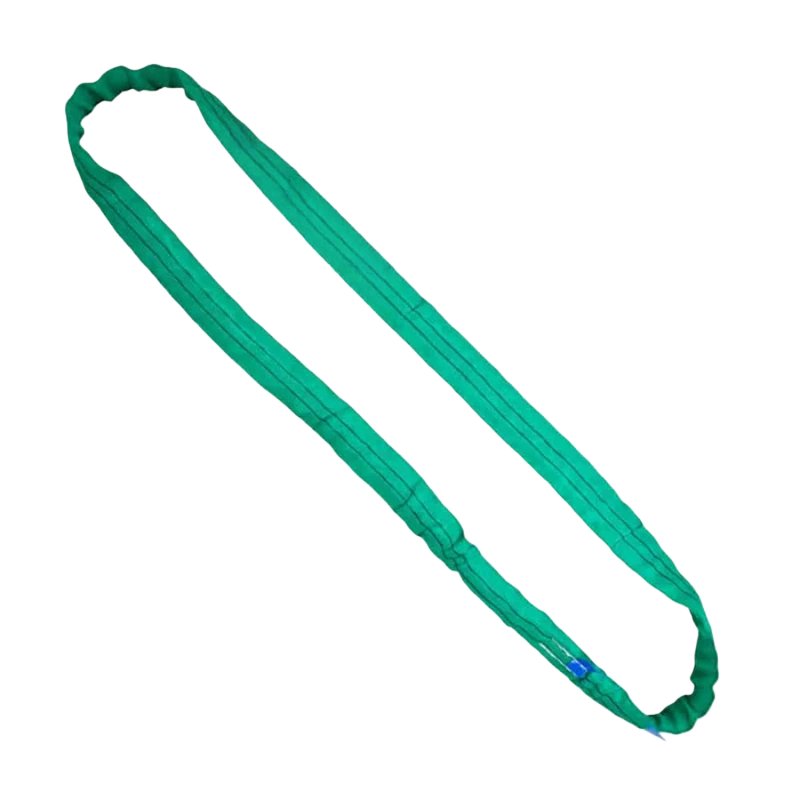

POLYESTER ROUND SLING SPECIFICATIONS

| Rated Capacity | (lbs.) | ||||

| TYPE | Color | Vertical | Chocker | U Vertical Basket | min hardware Dia(in) |

| CL-RS26 | PURPLE | 2600 | 960 | 2400 | 1/2 |

| CL-RS53 | GREEN | 5300 | 1920 | 4800 | 5/8 |

| CL-RS84 | YELLOW | 8400 | 2880 | 7200 | 3/4 |

| CL-RS132 | RED | 13200 | 3840 | 9600 | 1 |

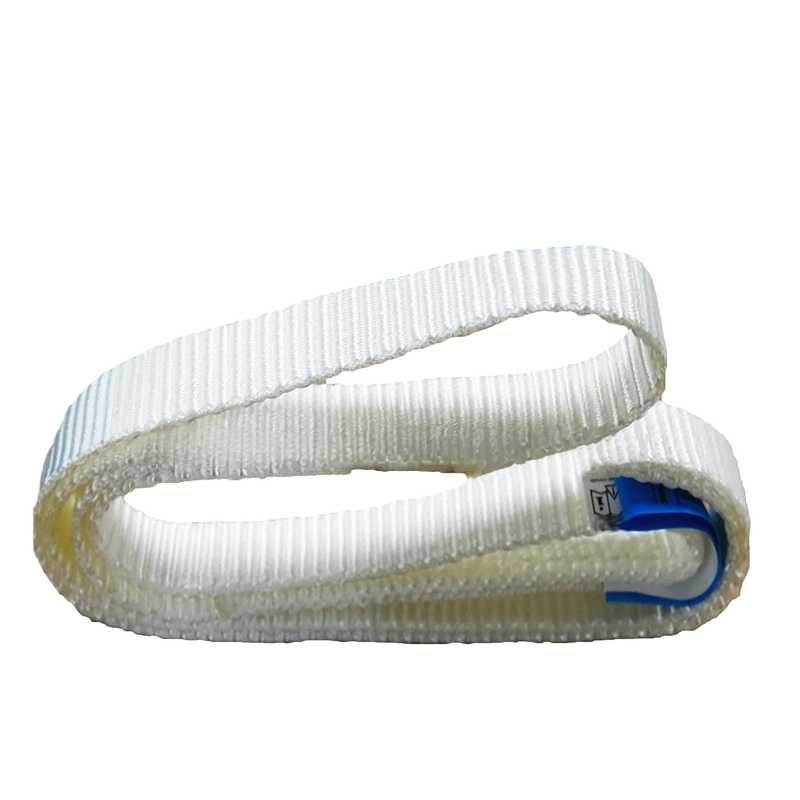

| CL-RS168 | WHITE | 16800 | 4800 | 12000 | 1 |

| CL-RS212 | BLUE | 21200 | 5760 | 14400 | 11/4 |

| CL-RS250 | ORANGE | 25000 | 2560 | 4800 | 11/2 |

POLYESTER ROUND SLINGS' INFORMATION

Compliance with Standards

All round slings meet or exceed the US standard ASME B30.9, ensuring safety and reliability for heavy-duty lifting tasks.

Double Jacket Protection

The slings are designed with a double jacket for extra durability and protection, increasing their lifespan and wear resistance.

Color-Coded Capacity

Each sling is color-coded to easily identify its lifting capacity, simplifying the selection process for different weight loads.

High-Quality Material

Made from 100% Polyester (PES), these slings offer low strain and are wear-resistant, providing long-lasting performance in demanding environments.

Customizable Length

Available in various lengths, the slings are measured from bearing point to bearing point, providing flexibility for different lifting applications.

Safety Rating

With a 5:1 safety factor, the Working Load Limit (WLL) is rated for vertical lifting, ensuring safe operations.

INSTRUCTIONS & CAUTIONS

Inspect Before Use

Always inspect the polyester round sling before each use. Check for any signs of damage, such as cuts, abrasions, or fraying. A visual check ensures the sling is safe to use and won’t fail under load. If any damage is found, replace the sling immediately to avoid accidents. Regular inspections help maintain safety standards and extend the sling’s lifespan.

Ensure Proper Load Weight

Make sure the load you are lifting does not exceed the Working Load Limit (WLL) indicated on the sling. Overloading the sling can lead to failure, causing injury or equipment damage. Each sling has a specific rated capacity, so always choose the correct sling for the job based on the weight and type of load. This ensures safe lifting operations every time.

Avoid Sharp Edges and Surfaces

Never allow the sling to come into contact with sharp edges or abrasive surfaces. These can damage the polyester material, weakening the sling and reducing its effectiveness. If you must lift loads with rough edges, use protective sleeves or pads to prevent wear and tear on the sling. Protecting the sling from sharp surfaces will prolong its life and improve safety.

Proper Storage

When not in use, store your polyester round sling in a dry, cool place away from direct sunlight, chemicals, and excessive moisture. Exposure to these elements can degrade the material and reduce the sling’s performance. Proper storage ensures the sling remains in good condition for future lifting tasks.

OUR ADVANTAGES

Tailored Solutions for Your Business

At Powerful Machinery, we take the time to understand your unique needs. We work closely with you to provide custom lifting solutions that fit your exact requirements. Whether it’s a special order or a specific lifting capacity, we’re here to help you find the right fit. Our personalized approach ensures your operations run smoothly and efficiently.

Quick Lead Time and Flexibility

We know that time is critical in your business. That’s why we prioritize fast lead times without compromising on quality. Whether you need bulk orders or smaller quantities, we offer flexible solutions that adapt to your schedule. Our efficient production processes and reliable delivery systems mean you get what you need when you need it.

Comprehensive Customer Support

We don’t just sell products—we offer ongoing support. Our dedicated team is available to answer any questions, offer guidance on product selection, and assist with any issues that arise. Whether it’s troubleshooting or technical advice, we’re always here to ensure your operations stay on track and you’re satisfied every step of the way.

Industry Expertise and Consistency

With years of experience in the lifting equipment industry, we bring a deep understanding of your challenges. We stay up-to-date with the latest industry standards and best practices, ensuring you receive products that meet all safety and quality requirements. Our consistent performance over time makes us a trusted partner for wholesalers, suppliers, and large supermarkets.

FAQ

What is a polyester round sling, and how is it used?

A polyester round sling is a flexible lifting tool made from strong polyester fibers. It’s used for lifting and moving heavy loads safely in various industries. The round design provides more strength and load distribution, preventing damage to the load. It’s commonly used in construction, manufacturing, and logistics for lifting equipment and materials.

Polyester Round Sling Inspection

-

Visual Inspection

Check for any visible cuts, abrasions, or fraying on the webbing. This ensures the sling hasn’t been damaged during previous use. -

Stitching Check

Inspect the stitching for any signs of wear, loosening, or damage. The stitching holds the sling together, so any weakness can compromise safety. -

Label Readability

Ensure the sling’s label is legible and displays the correct Working Load Limit (WLL). This is crucial for confirming that the sling is rated for the intended load. -

Chemical and UV Damage

Look for signs of chemical exposure or discoloration, which can weaken the polyester material. Discoloration may indicate degradation from exposure to harsh conditions. -

Overall Integrity

Evaluate the general condition of the sling for any signs of wear or damage. If there’s any doubt about the sling’s safety, replace it immediately.

What are the different sizes of polyester round slings available?

Polyester round slings come in a range of lengths and capacities, typically from 1 meter to over 10 meters. We offer customizable options to meet your specific lifting needs. The capacity varies depending on the sling’s size, so ensure you select one that matches your load’s weight and type. If you need specific sizes, we can provide custom-made slings for any lifting task.

Are polyester round slings suitable for lifting hazardous materials?

Polyester round slings are ideal for lifting non-abrasive, non-chemical loads. However, when lifting hazardous materials, you should ensure that the sling is compatible with the load’s characteristics. Always check for chemical resistance and ensure the sling won’t degrade due to exposure. For chemical or hazardous material handling, you may need specific slings with enhanced resistance.

Can polyester round slings be repaired?

Polyester round slings should not be repaired if damaged. Any damage to the webbing or stitching could compromise the sling’s strength and safety. It is highly recommended to replace damaged slings rather than attempt repairs. For safety, never use a damaged sling, and always inspect slings before use to ensure they are in good condition.

What are the benefits of using polyester round slings over wire rope slings?

Polyester round slings are lighter and more flexible than wire rope slings, making them easier to handle and less likely to cause damage to delicate loads. They also offer a higher level of load distribution, which reduces stress on the load and sling. Polyester slings are corrosion-resistant, unlike wire rope, making them ideal for a variety of environments, including wet or humid conditions.

What is the difference between single-ply and double-ply polyester round slings?

The main difference between single-ply and double-ply polyester round slings is the number of layers of polyester webbing. Double-ply slings offer increased strength, durability, and load-bearing capacity, making them ideal for heavy-duty lifting. Single-ply slings are lighter and more flexible, suitable for lighter lifting tasks. Choose the appropriate ply based on your lifting needs.

What should I do if the polyester round sling is not lifting evenly?

If the polyester round sling isn’t lifting the load evenly, check that the load is properly positioned and balanced. Uneven loads can cause stress on the sling, leading to wear or failure. Ensure the sling is appropriately sized for the load and that all lifting points are aligned. If you continue to experience issues, consult with an expert to ensure proper lifting techniques are used.