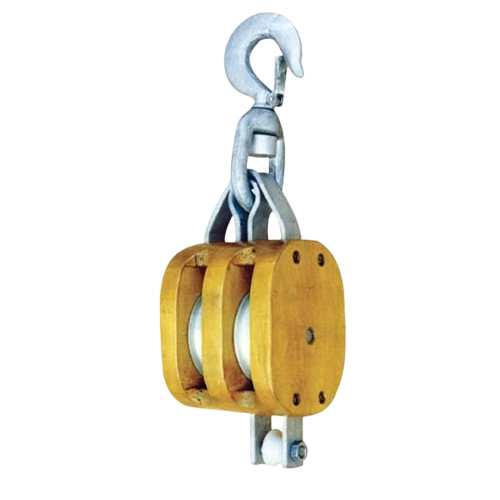

ROLLER SHACKLE SPECIFICATIONS

| SIZE | S.W.L | DIAM OF ROPE |

| (MM) | (TON) | (MM) |

| 25 | 3 | 20 |

| 28 | 4 | 24 |

| 32 | 5 | 34 |

ROLLER SHACKLE DESIGN

MATERIAL

- Body: High-strength forged steel

- Sheave: Cast iron or steel

- Finish: Hot-dip galvanized or painted

FEATURES

- Effortless and secure guidance for steel wire, fiber ropes, cables, and more.

- Stainless steel roller and pin for durability.

- Self-lubricating sliding bearings eliminate the need for external grease.

- Simple to rig and handle for convenience and efficiency.

STANDARDS

- Bureau Veritas

- Lloyd’s Register of Shipping

- American Bureau of Shipping

- Norwegian Maritime Authority

- Det Norske Veritas

- Germanischer LLoyds

APPLICATION

- For light lifting purpose.

INSTRUCTIONS & CAUTIONS

Inspect Before Use

Before every use, make sure to inspect the roller shackle for any signs of damage or wear, especially the swivel mechanism and pins. Look out for cracks, corrosion, or missing parts. If anything looks off, don’t use the shackle—safety first! Regular checks prevent accidents and ensure long-term performance.

Follow Load Limits

Always adhere to the safe working load (SWL) limits specified for the roller shackle. Overloading can weaken the components, leading to failures under stress. Make sure your lifting setup matches the load specifications to ensure maximum safety during operations. If you’re unsure, always err on the side of caution.

Lubricate When Necessary

Although many roller shackles have self-lubricating bearings, it’s still a good idea to check for adequate lubrication every so often. Keep the bearings free from debris and ensure smooth operation. When external lubrication is needed, use marine-grade grease to keep everything running smoothly and prevent wear.

Proper Storage

Store your roller shackles in a dry, clean area to avoid exposure to saltwater or chemicals, which can cause corrosion. If not in use for long periods, clean the shackle and apply a protective coating if necessary. Proper storage helps prolong the lifespan of your rigging equipment and keeps it ready for the next job.

OUR ADVANTAGES

Tailored to Your Needs

Looking for a customized solution? We offer tailored roller shackles to meet the specific requirements of your light lifting operations. Whether you need them for marine lifting, construction, or general rigging, we ensure the design suits your exact needs for the job.

Built for Reliability

Our roller shackles are built with durability in mind, using high-quality materials to ensure they perform reliably for light lifting purposes. They’re designed to handle the demands of everyday lifting jobs without compromise, making them a solid choice for short-term lifting and low-load operations.

Available in Stock

We keep a wide range of roller shackles in stock to ensure quick turnaround for your orders. Whether you need them for lifting or securing operations, we’ve got the right sizes and configurations ready to go. You won’t have to wait long for the gear you need.

Quick and Efficient Delivery

At Powerful Machinery, we focus on getting your custom roller shackles delivered quickly and safely. Our streamlined process ensures that you get your gear on time, so you can keep your projects running smoothly without delays. With reliable delivery, you can trust us to support your operations.

OUR REVIEWS

FAQ

What is a roller shackle?

A roller shackle is a lifting component designed for lifting and securing loads. It features a rotating roller that minimizes friction and reduces wear on cables or ropes, making it ideal for marine, construction, and rigging applications. Its durability and reliable design ensure it performs under heavy loads without compromising safety.

How does a roller shackle differ from a regular shackle?

The main difference is that a roller shackle has a swivel roller built into the design, which allows for smoother movement of cables and ropes. This feature reduces the stress on rigging equipment and increases its lifespan. Regular shackles, on the other hand, lack this smooth rotation, which can lead to more wear and tear during lifting operations.

How do I maintain a roller shackle?

1. Clean Regularly

After each use, rinse the roller shackle with fresh water to remove debris or salt buildup, ensuring its smooth operation.

2. Lubricate the Components

Apply marine-grade grease to the rollers and pins to reduce friction and prevent rust buildup, keeping the shackle in top condition.

3. Inspect for Wear and Damage

Regularly inspect the roller shackle for signs of wear, such as cracks or rust. If any parts appear damaged, replace them promptly to avoid safety risks.

4. Replace Worn Parts

Ensure any excessively worn parts are replaced to maintain safety and the integrity of the roller shackle.

5. Ensure Longevity and Safety

Regular maintenance of the roller shackle not only extends its lifespan but also ensures it remains safe for lifting operations.

What weight can a roller shackle safely lift?

The weight a roller shackle can safely lift depends on its size and rating. We offer a variety of roller shackles with different safe working loads (SWL), from 3 tons to 10 tons or more. Always ensure the shackle’s rated load capacity is suitable for your application, and never exceed the manufacturer’s recommended load limits to ensure safe operations.