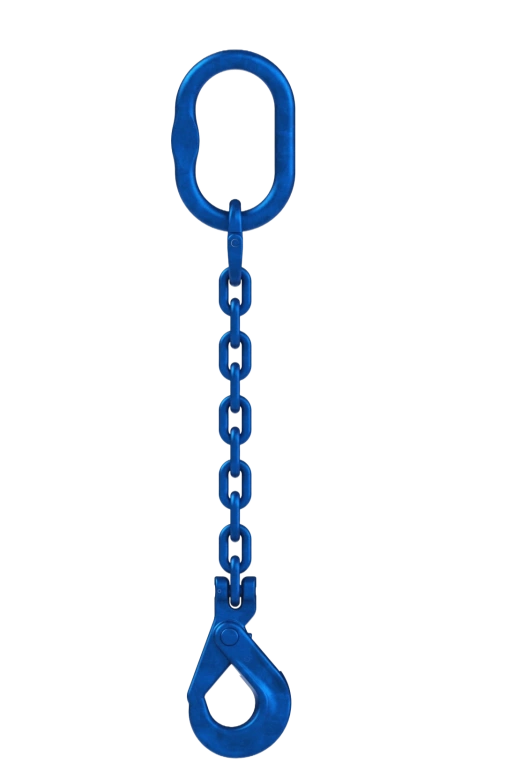

As a trusted chain sling manufacturer of single leg chain slings, we specialize in custom lifting solutions—whether small or oversized. Our focus is on delivering top-quality chains with strength-enhancing features like triple alloy (nickel, chromium, molybdenum) and single-weld links for added durability.

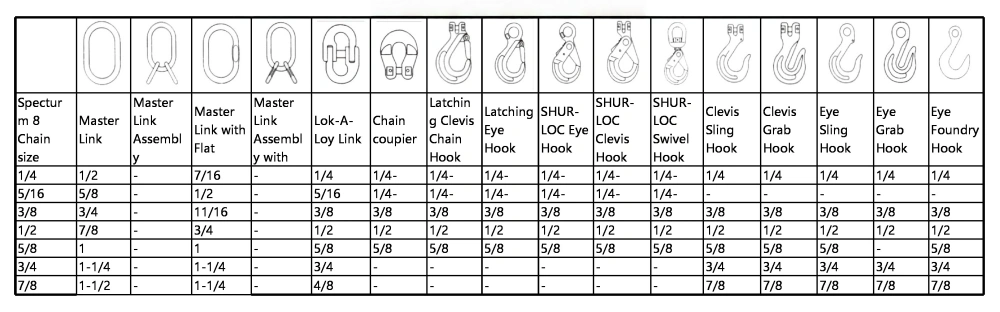

When ordering a custom single leg chain sling, please keep the following in mind:

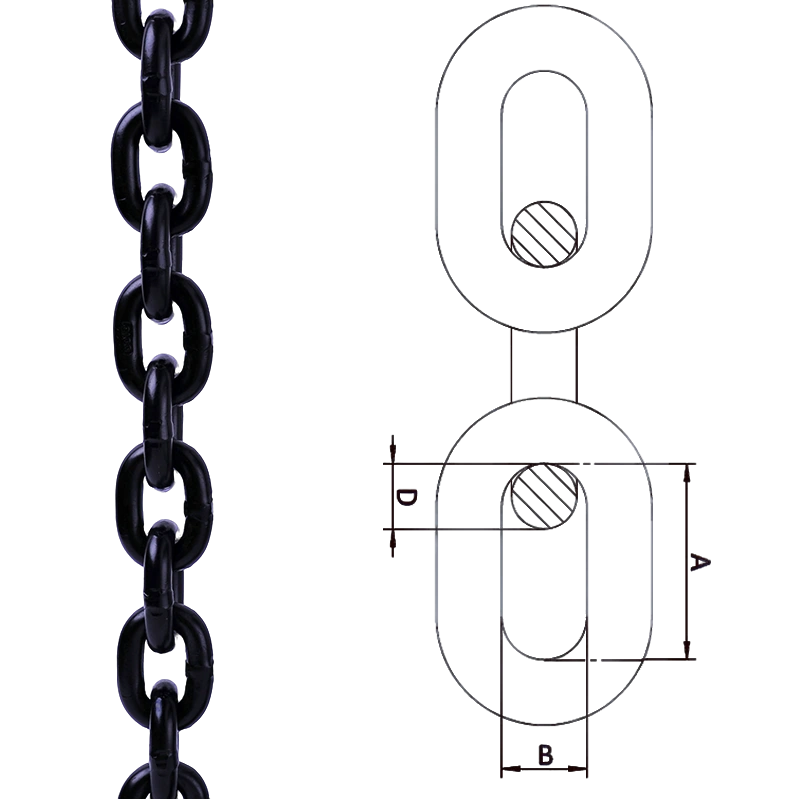

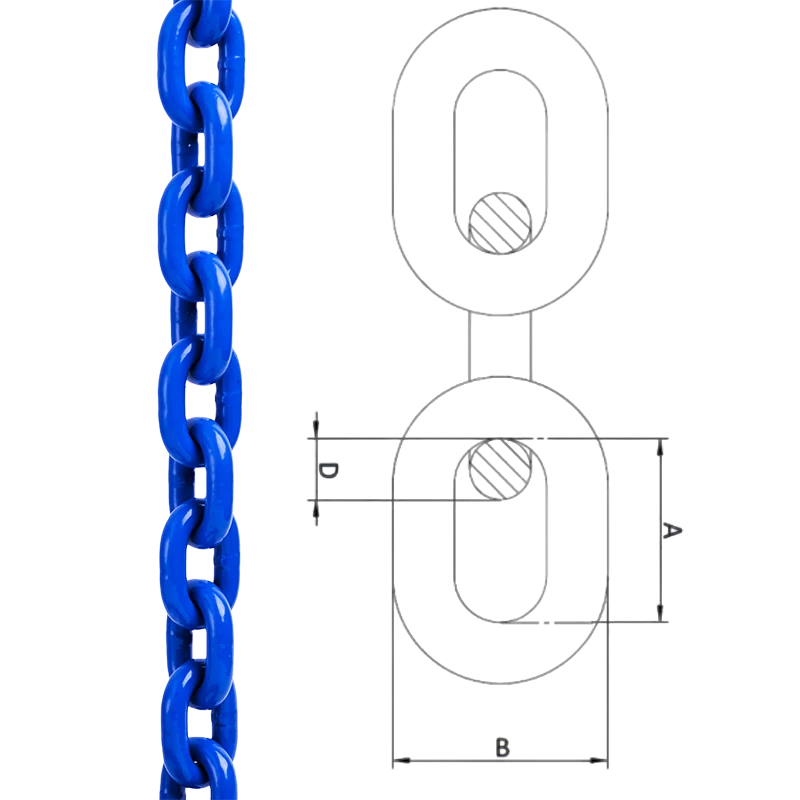

SIZE: This is based on the chain material size, determined by the required working load limit.

REACH: Measured from bearing point to bearing point, including all attachments.

ATTACHMENTS: Standard master links are used unless specified otherwise. If you need non-standard master links or hooks, please provide a detailed description or drawing.

TYPE: Specify the sling type, such as:

S = Single Leg

O = Oblong Link

S = Sling Hook (if required)

These details ensure that your single chain sling is built to your exact needs, providing the safety and reliability you expect.

DESIGN of SINGLE CHAIN SLING

GRADE

- 100

FINISH

- Blue Powder Coat Finish

STANDARDS

- Meets or exceeds ASTM A952, NACM, & OSHA 910 Standards

- Safety factor 4:1

- Fatigue Tested at 1.5 times the WLL for 20,000 cycles

- Proof Tested at twice the WLL

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

LINK TYPE

- Master Link

APPLICATION

- For overhead lifting

- Suited for use with wire rope, chain, and slings

MATERIAL

- Premium Fine Grain Alloy Steel

FAQ of 1 Leg Chain Lifting Slings

What is a single leg chain sling and when should you use it?

A single leg chain sling uses one chain leg connected to a master link and a hook, giving you direct vertical lifting strength and simple load control. You use it when the load has one strong lifting point or when you need straight-line force for machinery, engines, steel blocks, or pallets.

This design gives fast rigging, clear load paths, and easy inspection. Market demand stays strong because many construction and industrial lifts need speed, visibility, and reduced setup time.

You gain high strength, heat resistance, and durability compared with synthetic slings. Single leg slings also suit rental fleets and distributors because users understand them quickly and misuse risk stays lower with proper training.

How do you determine single leg chain sling capacity?

You determine capacity by checking chain diameter, grade, hook rating, and lifting direction. A single leg sling rates capacity only in vertical lifts, not angled lifts. Search data show capacity charts rank among the most searched chain sling topics because buyers want clear safety margins. A 10 mm Grade 80 chain often supports around 3.2 tonnes in vertical lift, while Grade 100 increases capacity with the same diameter.

You must match the weakest component rating, not the chain alone. Clear labeling helps users choose correctly and reduces overload incidents across construction, mining, and logistics sites.

How do you properly use single leg chain slings?

Correct use of a single leg chain sling ensures safe lifts, stable load control, and long service life in demanding industrial environments. Follow these practical steps to reduce risk and protect equipment.

Attach correctly: Connect the master link to a rated lifting device and secure the hook to a verified load point.

Lift vertically: Apply straight-line force and avoid side loading, tip loading, or off-angle pulls.

Protect the chain: Keep chains away from sharp edges and never wrap links around corners.

Check balance: Tension the sling slowly to confirm load balance before full lift.

Control the lift: Raise the load smoothly to prevent shock loading and chain distortion.

Preserve performance: Proper use reduces accidents and supports reliable sling performance in high-cycle operations.

How do you inspect a single leg chain sling before every lift?

Pre-use inspection of a single leg chain sling is critical for safe lifting and audit compliance across industrial worksites. A consistent inspection routine reduces downtime and prevents lift failures.

Check all components: Inspect the chain, master link, hook, and identification tag before use.

Look for damage: Watch for stretched or cracked links, corrosion, bent hooks, latch failure, or sharp nicks.

Verify identification: Confirm the tag remains readable and shows grade, size, and working load limit.

Remove from service: Take the sling out of use immediately if any defect appears.

Meet safety audits: Regular inspection supports compliance during site inspections and safety reviews.

Protect operations: Routine checks safeguard crews, equipment, and schedules in construction, oil fields, and shipyards.

How often should single leg chain slings receive formal inspection?

You schedule formal inspections at least once per year under normal conditions. You increase frequency under heavy use, harsh environments, or rental service. A qualified inspector documents wear, measurements, and repair decisions. Inspection records support compliance and liability protection. Consistent inspection programs extend service life and reduce emergency replacement costs.

How should you store single leg chain slings?

Proper storage of single leg chain slings plays a direct role in safety, service life, and inspection readiness. Correct handling prevents premature wear even in demanding industrial environments.

Choose the right area: Store slings in clean, dry locations away from moisture and corrosive chemicals.

Hang correctly: Suspend chains off the floor to prevent twisting, kinking, or link deformation.

Protect identification: Keep tags visible and readable for quick inspection and compliance checks.

Preserve strength: Proper storage maintains heat treatment and correct link geometry.

Extend lifespan: Good handling practices reduce early failure, even when using premium-grade chain slings.