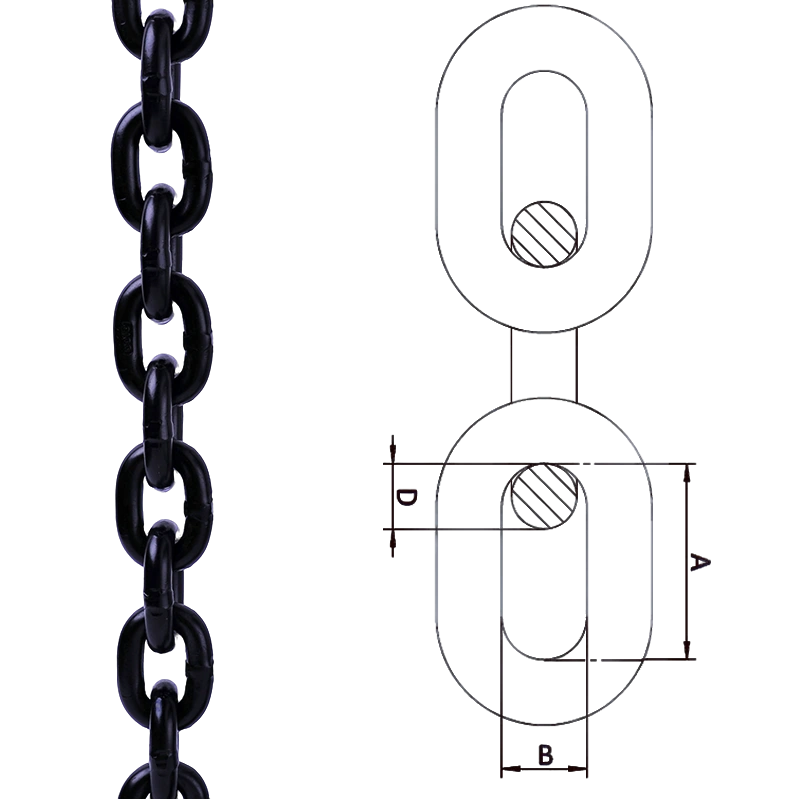

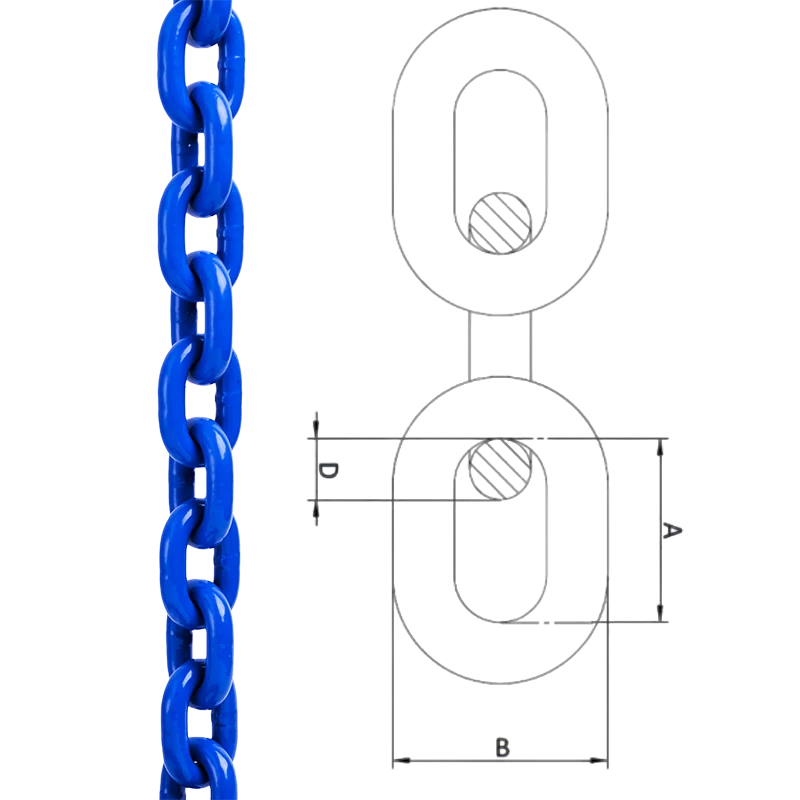

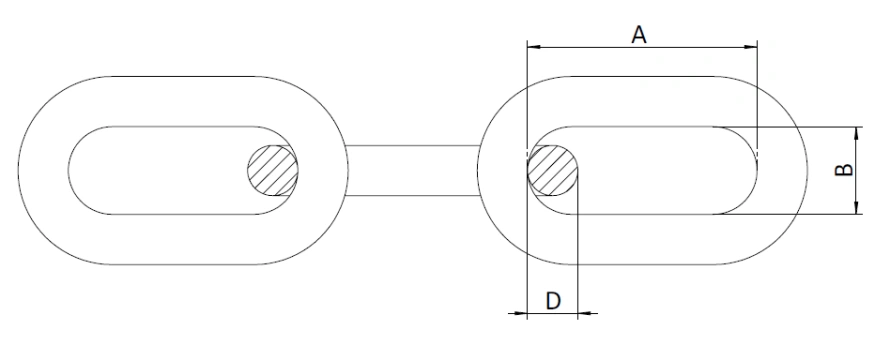

DIAGRAMS of STUDLESS CHAIN

STUDLESS LINK CHAIN SPECIFICATIONS

| TESTING LOAD OF STUDLESS CHAINS | |||||||

| Dia. | BM1 (KN) | BM2 (KN) | BM3 (KN) | Weight | |||

| mm | Breaking Load | Proof Load | Breaking Load | Proof Load | Breaking Load | Proof Load | kg/m |

| 16 | 94.72 | 47.1 | 132.3 | 66.2 | 184.83 | 92.42 | 5.56 |

| 17.5 | 113.31 | 56.35 | 157.78 | 78.89 | 221.1 | 110.55 | 6.65 |

| 19 | 133.57 | 66.42 | 187.2 | 93.6 | 260.64 | 130.32 | 7.83 |

| 20.5 | 155.49 | 77.33 | 217.27 | 108.64 | 303.42 | 151.7 | 9.12 |

| 22 | 179.08 | 89.06 | 250.9 | 125.4 | 349.4 | 174.7 | 10.5 |

| 24 | 213.25 | 105.98 | 298 | 149.9 | 415.8 | 207.9 | 12.5 |

| 26 | 250.12 | 124.38 | 350.8 | 175.4 | 488 | 244 | 14.67 |

| 28 | 290.08 | 144.26 | 406.7 | 203.8 | 566 | 283 | 17 |

| 30 | 333 | 165.6 | 467.5 | 234.2 | 649.8 | 324.9 | 19.5 |

| 32 | 378.88 | 188.42 | 531.2 | 265.6 | 739.3 | 369.6 | 22.22 |

| 34 | 427.72 | 212.7 | 599.8 | 299.9 | 834.6 | 417.3 | 25.08 |

| 36 | 479.52 | 238.46 | 672.3 | 336.1 | 935.7 | 467.8 | 28.12 |

| 38 | 534.28 | 265.7 | 748.7 | 374.4 | 1042.5 | 521.3 | 31.33 |

| 40 | 592 | 294.4 | 829.1 | 414.5 | 1155.2 | 577.6 | 34.72 |

| 42 | 652.68 | 324.58 | 915.3 | 457.7 | 1273.6 | 636.8 | 38.28 |

| 44 | 716.32 | 356.22 | 999.6 | 502.7 | 1397.8 | 698.9 | 42.01 |

| 46 | 782.92 | 389.34 | 1097.6 | 548.8 | 1527.8 | 763.9 | 45.92 |

| 48 | 852.48 | 423.94 | 1195.6 | 597.8 | 1663.5 | 831.7 | 50 |

| 50 | 926.09 | 460 | 1293.6 | 648.8 | 1805 | 902.5 | 54.25 |

DESIGN of STUDLESS LINK ANCHOR CHAIN

MATERIAL

- Galvanized Steel, AISI 316 Stainless Steel, or Carbon Steel

WARNING

- This chain is not suitable for lifting purposes.

FINISH

- Hot-Dip Galvanized

- Painted/Coated

- Electro-Galvanized

STANDARDS

- ISO standards

APPLICATION

- Specifically designed for anchoring applications on ships and vessels.

CUSTOMIZATION

- Available

INSTRUCTIONS & CAUTIONS

WORKING LOAD LIMITS: This is the maximum load a chain should ever handle, even when it’s new and the load is evenly distributed along a straight, untwisted length. The “working load limit” doesn’t reflect the load the chain could potentially endure if conditions like wear, twisting, misuse, overloading, or corrosion are introduced. These factors can reduce the chain’s strength, so regular inspections are crucial to ensure safety.

PROOF TEST: This is the load a chain undergoes before leaving the factory. The chain is tested under direct tension in a straight line at a consistent speed using a standard testing machine. The purpose of this test is to identify any material or manufacturing defects.

All stud link chain,studless anchor chain and mooring chain are proof tested. are proof tested. When using attachments like hooks or rings, make sure they match the chain’s grade, type, and size for proper load-bearing performance.

OUR ADVANTAGES

Tailored Customization

We provide custom ISO standard studless link anchor chain to fit your specific needs. Whether it’s size, material, finish, or strength grade, we’ve got you covered. This flexibility makes our chains ideal for everything from industrial to agricultural and marine applications.

Built to Last

Our chains are made from high-quality materials like carbon steel and stainless steel, designed to perform under tough conditions. They resist corrosion, handle heavy use, and keep working long-term, no matter how demanding the environment.

Industry-Approved

All our chains are made to meet ISO standards and other relevant certifications, so you can trust their safety and reliability. We ensure that every chain performs to the highest specifications, keeping you compliant with industry regulations.

Great Value with Bulk Discounts

Get the best value for your money with our competitive pricing and bulk discounts for large orders. We make sure you get a great deal without compromising on the quality of our ISO standard studless chain .

FAQ of STUDLESS MOORING CHAIN

What is a studless anchor chain?

A studless anchor chain is a type of chain commonly used in marine and anchoring applications. It’s designed without internal studs, making it more flexible than studlink chains. Studless chains are typically used in environments where flexibility, ease of handling, and moderate strength are needed. They’re resistant to corrosion and wear, ensuring reliable performance in harsh marine conditions.

Stud link vs studless chain : Which is better for anchoring?

When choosing between stud link and studless chains for anchoring, it depends on your specific needs. Here’s a comparison to help you decide which is best for your application:

-

Stud Link Chains: These chains feature studs that add extra strength and durability. They are ideal for deep-sea anchoring, as the studs provide additional resistance to wear and tear, ensuring long-term performance under heavy load. Stud link chains also have a higher breaking strength, making them reliable for large vessels.

-

Studless Chains: On the other hand, studless chains offer more flexibility. They are smoother, which reduces friction and allows for better handling in harsh conditions. These chains are often preferred for shallow water applications, as they are lighter and easier to handle, but still provide adequate strength for typical anchoring needs.

-

Load Considerations: If you’re working in areas with high currents or deep water, a stud link chain’s added strength may be the better choice. Studless chains are more suitable for applications where ease of use and flexibility are top priorities.

Are studless anchor chains suitable for lifting applications?

Studless anchor chains are not designed for lifting heavy loads. They are intended for anchoring and securing vessels in place rather than lifting. For lifting applications, you should use chains specifically rated for lifting purposes, like Grade 80 or Grade 100 alloy chains, which are designed for safe, dynamic load-bearing.

Can studless anchor chains be used in saltwater environments?

Yes, studless anchor chains are ideal for saltwater environments. They are made from corrosion-resistant materials such as galvanized steel or stainless steel, making them resistant to the effects of saltwater. This ensures a long service life and reliable performance without degradation from rust or corrosion, which is crucial for marine and offshore applications.

Are studless anchor chains customizable in length?

Yes, studless anchor chains can be customized to your required length. Whether you need a shorter chain for a small vessel or a longer chain for larger ships, we offer customization options to meet your needs. Custom lengths ensure that the chain fits your anchoring system perfectly, providing better control and performance in all conditions.

How should I maintain a studless anchor chain?

-

Regular Inspections: Check for wear, corrosion, and damage regularly to ensure the chain remains in good condition.

-

Wash with Fresh Water: Periodically wash the chain to remove salt buildup, especially after exposure to saltwater.

-

Apply Rust Inhibitor or Lubricant: Use a light coat of rust inhibitor or chain lubricant to maintain smooth operation and prevent corrosion.

-

Proper Storage: When not in use, store the chain properly to extend its lifespan and protect it from environmental damage.

Are studless anchor chains compatible with all anchors?

Yes, studless anchor chains are compatible with most types of anchors, provided that the chain’s size and strength are appropriate for the anchor’s requirements. The chain can be connected to the anchor using shackles or rings, making it adaptable to various anchoring systems, ensuring secure attachment and effective holding power.

What are the benefits of using a studless anchor chain over a studlink chain?

The main benefit of studless chains is their flexibility and ease of handling. Unlike studlink chains, which are stiffer and harder to manage, studless chains are more adaptable and easier to store. They are ideal for lighter-duty anchoring, where flexibility and ease of use are more important than maximum strength. Studless chains are also typically lighter, making them easier to deploy.

What certifications do studless anchor chains have?

Studless anchor chains are often certified by international standards organizations such as RINA, BV, or Lloyd’s Register. These certifications ensure that the chain has been tested for safety, durability, and performance under the harshest conditions. Certified chains give you peace of mind that you are using equipment that meets the highest industry standards.