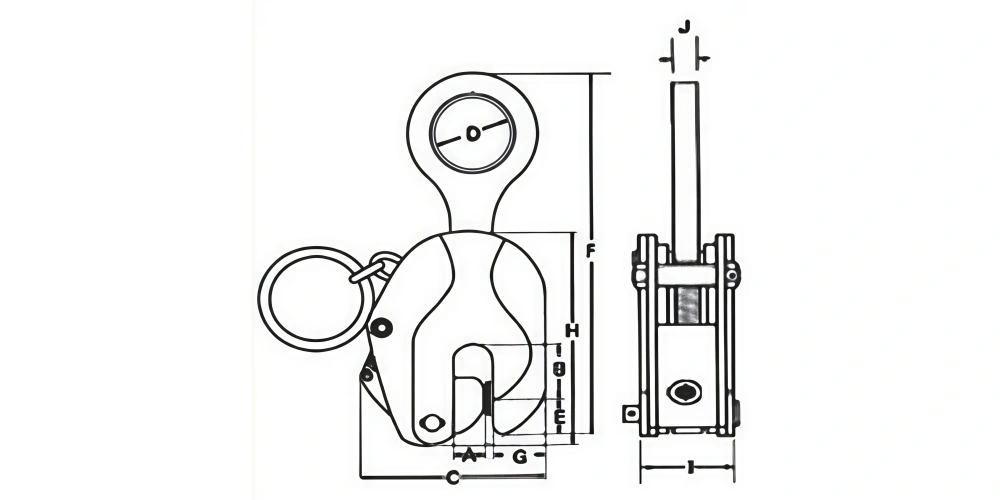

VERTICAL LIFTING CLAMP DRAWING

VERTICAL PLATE LIFTING CLAMP SPECIFICATIONS

| Dimensions(mm) | ||||||||||||||

| Model | Capacity (ton) | Running test load (KN) | Opening Size (MM) | A | B | C | D | E | F | G | H | 1 | J | Net weight(KG) |

| E-0001 | 1000 | 19.6 | 0-22 | 24 | 36 | 125 | 50 | 24 | 220-260 | 30 | 156 | 52 | 14 | 3.6 |

| E-0002 | 2000 | 39.2 | 0-30 | 35 | 45 | 155 | 60 | 30 | 250-295 | 38 | 190 | 60 | 18 | 6 |

| E-0003 | 3000 | 58.8 | 0-35 | 40 | 50 | 175 | 60 | 35 | 296-360 | 40 | 226 | 68 | 20 | 9.2 |

| E-0005 | 5000 | 98 | 0-50 | 50 | 58 | 218 | 65 | 42 | 350-420 | 60 | 270 | 76 | 22 | 16.5 |

| E-0010 | 10000 | 148 | 0-90 | 90 | 120 | 325 | 82 | 60 | 454 | 75 | 333 | 95 | 25 | 33 |

VERTICAL PLATE LIFTING CLAMPS FEATURES

Working Load Limit (WLL)

-

0.8 to 16 tons, suitable for a wide range of industrial lifting tasks.

Usage

-

Designed for vertical lifting of steel plates and steel structures in industrial settings.

Safety Features

-

Spring Locking Mechanism: Prevents slipping and ensures a secure grip during lifting.

-

Latch-Type Safety Lock: Spring-loaded mechanism guarantees safe and easy operation.

Material & Construction

-

High-Quality Steel: Made from low-carbon alloy steel for durability and strength.

-

Induction-Hardened Alloy Steel Cam: Offers enhanced durability and wear resistance.

-

High-Tensile Steel Construction: Welded, crack-resistant body for maximum strength.

Durability

-

Heat-Treated Toothed Plate: Special alloy steel with heat treatment for increased strength and longevity.

-

Epoxy Baked Finish: Provides resistance to corrosion for long-lasting performance.

Design Features

-

Round Swivel Jaw: Ensures a secure grip on various steel materials.

-

Large Universal Shackle: Allows easy handling and attachment of lifting slings.

-

Lightweight & User-Friendly: Easy to use, increasing lifting efficiency.

Precautions

-

Avoid collision with the suspended object to ensure safety during lifting operations.

INSTRUCTIONS & CAUTIONS

Check Load Capacity

Before using the vertical lifting clamp, always ensure the load does not exceed its working load limit (WLL), which ranges from 0.8T to 16T. Overloading the clamp can cause safety risks or damage to both the clamp and the load. Be sure to verify the clamp’s load rating before each lift.

Ensure Secure Attachment

Make sure the clamp is properly secured on the load before lifting. Engage the locking mechanism fully and double-check its placement on the steel plate or structure. A loose or improperly positioned clamp could cause slippage or result in an unsafe lift.

Avoid Contact During Lifting

During the lifting process, avoid any impact or collision with other objects. Impact can weaken the clamp’s grip and compromise safety. Ensure that the load is stable and clear of obstructions to minimize risks.

Regular Inspections & Maintenance

Inspect the clamp regularly for signs of wear, damage, or cracks, particularly after heavy use. Keep the moving parts well-lubricated to ensure smooth operation. If you notice any damage, replace the clamp immediately to maintain safe lifting operations.

OUR ADVANTAGES

Customized Solutions for Your Business

At Powerful Machinery, we know every business has unique needs. That's why we provide tailored solutions designed to fit your specific lifting requirements. Whether it’s for a complex project or a routine operation, we work closely with you to deliver equipment that maximizes efficiency, safety, and performance for your business.

Expert, On-Demand Support

We’re not just a supplier; we’re a partner. Our experienced team is always ready to offer expert advice and support whenever you need it. Whether it’s troubleshooting, training, or guidance on optimal use, we ensure your equipment operates at peak performance, helping your business stay on track and efficient at all times.

Dependable, High-Quality Equipment

We focus on producing durable and reliable lifting equipment that meets high industry standards. Using top-quality materials and advanced manufacturing methods, we ensure our products deliver consistent performance, even under heavy-duty conditions. With Powerful Machinery, you get long-lasting, dependable equipment that can handle the toughest tasks.

Fast Delivery and Quick Turnaround

We understand that time is critical for your operations. Our streamlined production and logistics systems guarantee fast turnaround times, ensuring your equipment is delivered on schedule. This means you can reduce downtime, keep your operations running smoothly, and meet your business demands without delays.

FAQ

Can vertical lifting clamps be used for lifting various steel shapes?

Yes, these clamps are designed to lift different steel shapes, from flat plates to more complex structures. However, to avoid any issues, it’s important to choose a clamp that fits the dimensions and weight of your load. Let us know your requirements, and we can recommend the best clamp for your lifting needs.

How do I avoid damaging the load while using vertical lifting clamps?

To minimize the risk of surface damage, always choose clamps specifically designed for the material you’re lifting. Many models are designed with protective features, like soft jaws or coatings. Make sure the clamp is properly attached to prevent unnecessary strain on the load.

Can vertical lifting clamps be used for both horizontal and vertical lifting?

While these clamps are mainly designed for vertical lifting, certain models can handle both orientations. If you need a multi-directional clamp, we can guide you to the right product for your specific lifting application.

Can vertical lifting clamps be used for lifting other materials besides steel?

While vertical lifting clamps are primarily designed for steel, some models may work with other materials like aluminum or concrete. It’s important to check compatibility before use. If you’re lifting different materials, let us know, and we can recommend the right clamp for your needs.

How can I get a quote for vertical lifting clamps?

-

Provide Load Details: Share information about the load you’re lifting, including its weight and dimensions.

-

Specify Materials: Let us know the materials involved in the lifting process (e.g., steel, aluminum, etc.).

-

Include Specific Requirements: Mention any unique needs or conditions for the lifting task (e.g., environmental factors, clamp type).

-

Receive a Competitive Quote: Our team will review your details and provide a tailored quote for your project.

-

Contact Us Today: Reach out to us to get started. We’ll respond promptly with the best options for your needs.