PRODUCT FEATURES

MATERIAL

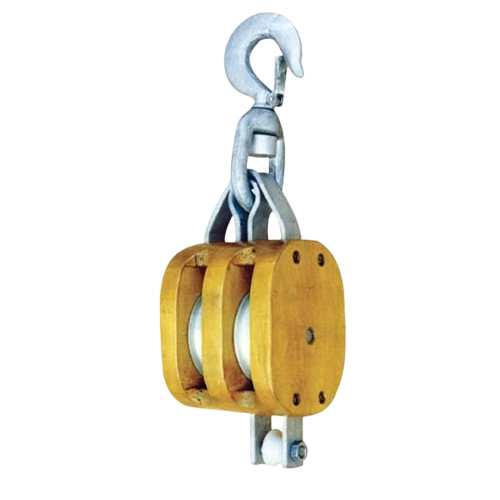

- Hardwood Shells

Design Variations

- Available with a variety of fittings: Swivel eye/Swivel hook/Anchor shackle/Hooks with latch

Performance & Durability Features

- Drop Forged Fittings

- Self-Lubricating Bushings

- Galvanized Metal Parts

Sheave Options

- Available in single, double, or triple sheave configurations

APPLICATION

- These blocks are available for use with Manila rope, and are equipped with drop-forged fittings, offering strong performance for lifting tasks.

WOOD SHELL BLOCKS SPECIFICATIONS

| SIZE | S.W.L | DIAM OF ROPE |

| (IN) | (LBS) | (IN) |

| 3 | 1200 | 3/8 |

| 4 | 1800 | 1/2 |

| 5 | 2400 | 5/8 |

| 6 | 3200 | 3/4 |

| 8 | 4800 | 1 |

| 10 | 8000 | 1 1/8 |

| 12 | 10000 | 1 1/4 |

INSTRUCTIONS & CAUTIONS

Inspect the Block Before Every Use

Always take a moment to inspect the block before use. Look for any signs of wear, cracks, or damage, especially on the wood shell and hook. If you spot any issues, don’t use it—get it replaced or repaired. Remember, this is a simple step that can save you a lot of trouble down the line.

Follow the Working Load Limit

Be cautious about the load you’re lifting. Overloading the block can damage the wood shell, hook, or fittings, and compromise safety. Always assess the total load beforehand and make sure it’s within the block’s capacity. We’ve put the blocks through thorough quality tests, but overloading can still lead to damage.

Use the Right Rope Size

Make sure you’re using the proper size rope with the block. Using a rope that’s too thick or too thin can cause friction or disrupt the block’s performance. Always check that the rope is threaded properly and securely in place for smooth operation.

Handle With Care

Treat the block with care to avoid unnecessary wear. Don’t drop it or subject it to excessive force, as this can cause damage to the wood, hook, or bushings. Even though we’ve tested the blocks for quality, rough handling can still lead to issues down the line.

OUR ADVANTAGES

Powerful Machinery is focused on one thing: supplying professionals in the construction, marine, transportation, and cargo handling industries with premium lifting equipment, rigging and lifting hardware at competitive prices.

We offer preferred pricing to resellers and distributors. Contact us if you’d like info on becoming a partner.

Direct from Manufacturer

At Powerful Machinery, we cut out the middleman. We design and produce our triple wood shell blocks with hooks in-house, meaning you get top-quality equipment at better prices. Without extra layers of distribution, we offer faster delivery, direct customer service, and full control over the quality of every block we make.

Quality & Safety First

We don’t compromise on safety or quality. Our blocks are built tough, using only the best materials, and we make sure they pass all necessary tests before they leave our factory. You can trust that every block will hold up in even the toughest conditions, keeping both your crew and your load safe.

One-Stop Sourcing

Why shop around when you can get everything in one place? From triple wood shell blocks to all the hooks, shackles, and ropes you need, we’ve got you covered. It makes your job easier and saves you time—just place one order, and we’ll take care of the rest.

Custom Solutions Tailored to You

We know every job is different. If you need something a little more specialized, we’re here to help. Whether it’s adjusting the sheave size or adding specific fittings, we can tailor our blocks to fit your needs perfectly, so you get exactly what you require for the job.

OUR REVIEWS

FAQ

How do I choose the right size wood shell block

Choosing the right wood shell block depends on the load weight, the type of rope you’re using, and the size of the sheave you need. For optimal performance, ensure the block is compatible with your rope size and working load limit. If you’re unsure, consult the product specifications or talk to us. We can help you find the perfect block for your application, ensuring safe and efficient lifting every time.

Can wood shell blocks be customized?

Yes, wood shell blocks can be customized to meet your specific needs. We offer custom solutions like adjusting sheave sizes, adding or modifying fittings, and selecting specific materials for bushings and hooks. Whether you need something tailored for a unique lifting task or specific rope types, we’ll work with you to create the perfect block to fit your system, ensuring maximum efficiency and safety.

How do I maintain wood shell blocks?

-

Clean Regularly

Clean wood shell blocks frequently to remove dirt, debris, and any buildup that could affect performance. -

Inspect for Wear or Damage

Regularly check the wood shell and fittings for any signs of cracks, wear, or damage. Pay special attention to the hooks, sheaves, and bushings. -

Check for Rust or Corrosion

Examine the hooks, sheaves, and bushings for any rust or signs of corrosion. Address these issues promptly to prevent further damage. -

Lubricate When Necessary

Keep the moving parts lubricated to ensure smooth operation and reduce friction that can cause wear. -

Store in a Dry, Clean Area

When not in use, always store wood shell blocks in a dry, clean environment to protect them from moisture and environmental damage. -

Regular Maintenance for Longer Lifespan

Routine maintenance not only helps maintain safety and performance but also extends the lifespan of your wood shell blocks, ensuring reliable operation.

How do I install a wood shell block?

Installing a wood shell block is straightforward, but safety is key. Start by securely attaching the hook or fitting to your rigging system, ensuring it’s tightly fastened. Then, thread the rope through the sheaves, making sure the rope sits properly without any twists or tangles. Always test the block with a light load before full use to ensure everything is working as expected and no parts are compromised.

Can wood shell blocks be used in high-temperature environments?

Wood shell blocks are generally designed to withstand a range of temperatures. However, extremely high or low temperatures can affect the wood’s integrity and the performance of metal components. If you’re planning to use wood shell blocks in very high-temperature environments, it’s crucial to consider the specific conditions and consult with us for recommendations. We can offer specialized solutions for extreme conditions if needed.

Can wood shell blocks be used in lifting systems with multiple pulleys?

Yes, wood shell blocks can be used in multi-pulley systems, as long as the rope size and working load limits are compatible with the system. Ensure that all components of the rigging, including pulleys and hooks, are rated for the weight you plan to lift. Multi-pulley systems are often used to distribute the load evenly, making it essential to use high-quality blocks to ensure smooth operation and prevent wear from friction.