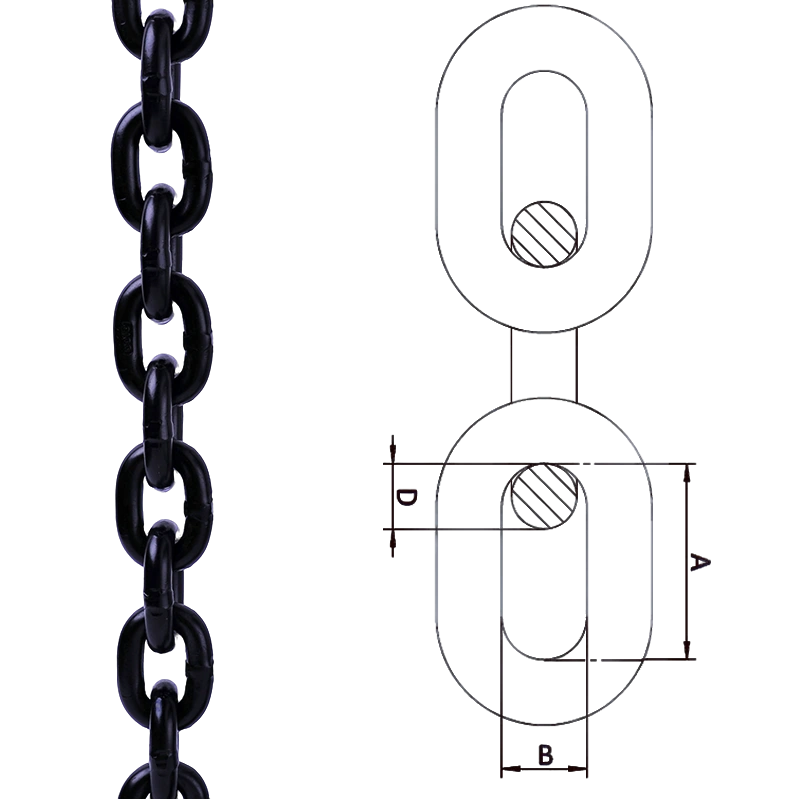

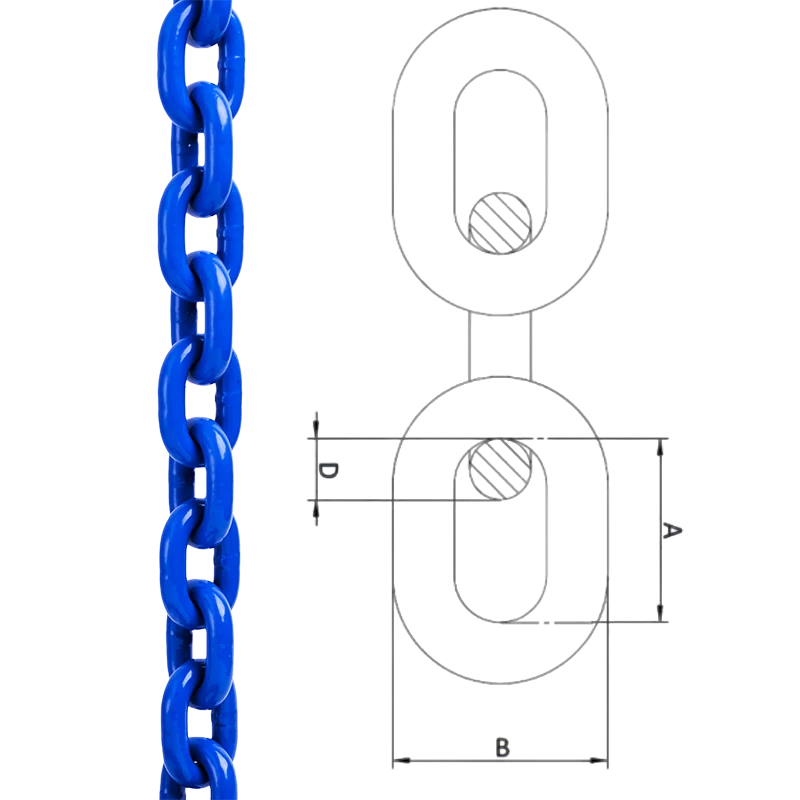

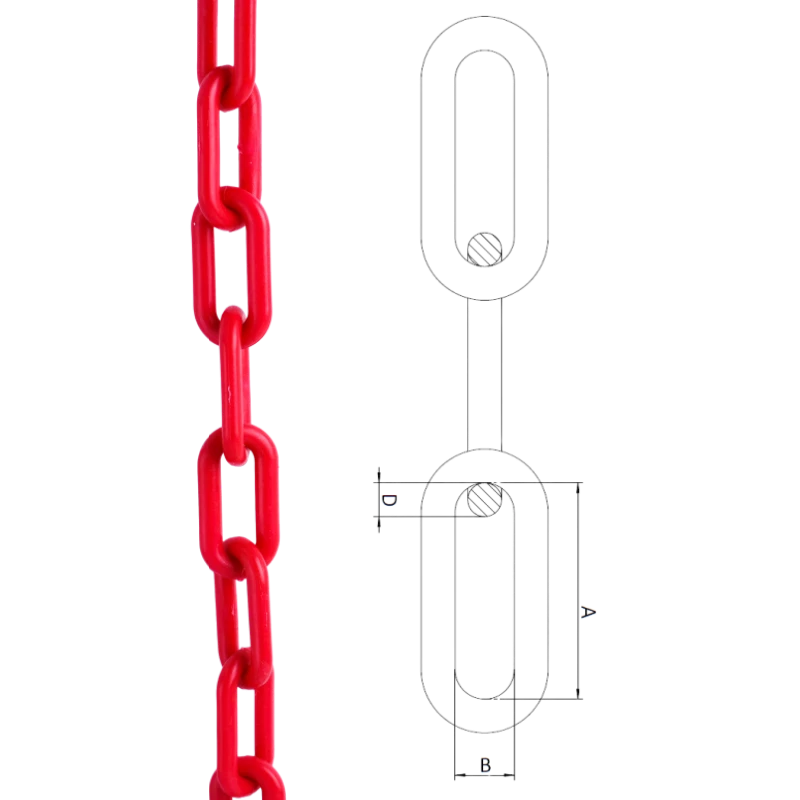

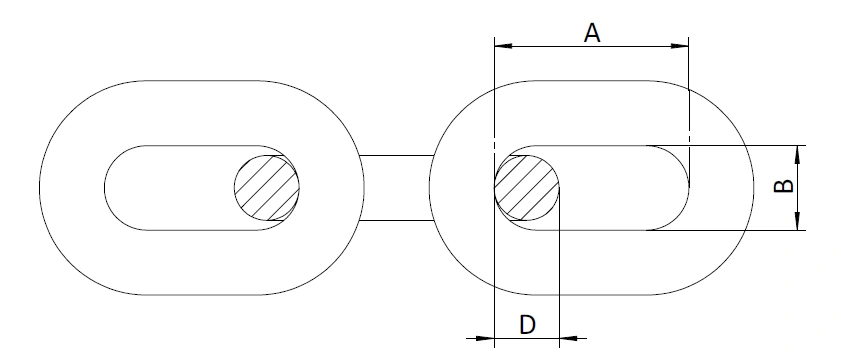

DIAGRAMS

GRADE 80 LIFTING CHAIN SPECIFICATIONS

| Dia d mm | Inside Length (A)mm | Inside Width (B) | Weightkg/m | Working Load Limit ton | Manuf. Proof Force KN | Min Breaking Force KN |

| 5 | 16 | 0.56 | 0.80 | 19.6 | 31.4 | |

| 6 | 18 | 7.8 | 0.80 | 1.12 | 28.3 | 45.2 |

| 7 | 21 | 9.1 | 1.10 | 1.50 | 38.5 | 61.6 |

| 8 | 24 | 10.4 | 1.40 | 2.00 | 50.3 | 80.4 |

| 10 | 30 | 13 | 2.20 | 3.15 | 78.5 | 126 |

| 13 | 39 | 16.9 | 3.80 | 5.30 | 133 | 212 |

| 16 | 48 | 20.8 | 5.70 | 8.00 | 201 | 322 |

| 19 | 57 | 8.00 | 11.20 | 284 | 454 | |

| 22 | 66 | 28.6 | 10.80 | 15.00 | 380 | 608 |

| 26 | 78 | 33.8 | 15.20 | 21.20 | 531 | 849 |

| 32 | 96 | 41.6 | 23.00 | 31.50 | 804 | 1280 |

DESIGN

GRADE

- G80

FINISH

- Black Thermadep or Silver Shield

STANDARDS

- Meets or exceeds OSHA, Government, NACM, and ASTM specification requirements

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

APPLICATION

- Overhead Lifting/Rigging

MATERIAL

- Special analysis alloy steel

Our Advantages

Flexible Payment

Choose from a range of payment options to suit you such as a 30-day credit account.

Fast Delivery

Enjoy fast delivery with quick processing and timely arrivals for all your orders.

Best Rated

We Are the Highest Rated Lifting Chains Manufacturer in China With 20 Years of Experience & Knowledge

Price Match Guarantee

We are committed to offering the best prices and ensuring you never pay more than necessary.

FAQ of G80 Lifting Chain

What is Grade 80 lifting chain?

Grade 80 lifting chain is an alloy steel chain designed specifically for overhead lifting and critical load handling. You use Grade 80 lifting chain with cranes, hoists, and chain slings where safety margins matter. Alloy steel composition and controlled heat treatment give each link high strength with stable elongation. Manufacturing precision ensures predictable performance across repeated lifts. You rely on Grade 80 lifting chain because it maintains shape under stress and supports demanding lifting cycles without distortion.

What defines Grade 80 lifting chain

-

Alloy steel construction

-

Heat-treated strength profile

-

Approved for overhead lifting

-

Consistent link geometry

-

Clear grade markings

What is the Grade 80 chain working load limit?

The working load limit defines how much weight Grade 80 lifting chain can safely handle during normal lifting conditions. You base lift planning on this value to protect people, equipment, and schedules. Manufacturers calculate working load limits using chain diameter, material strength, and safety factors. You must consider sling angles and dynamic forces because real lifts rarely stay perfectly vertical. Staying within the working load limit preserves chain life and lifting reliability.

Factors that affect working load limit

-

Chain diameter

-

Sling leg configuration

-

Lift angle

-

Load movement

-

Shock forces

What does the G80 chain rating mean?

The G80 chain rating identifies the chain as Grade 80 lifting chain suitable for overhead use. You see this rating stamped on each link or tag for clear identification. The rating confirms strength level, material grade, and compatibility with Grade 80 fittings. Manufacturers proof test and break test chains to verify rating accuracy. You depend on this rating to match chain performance with hoists and lifting accessories.

What the G80 rating confirms

-

Approved lifting grade

-

Defined working load limit

-

Compatibility with G80 components

-

Traceable production batches

-

Inspection-ready identification

How strong is Grade 80 lifting chain?

Grade 80 lifting chain delivers high tensile strength with controlled flexibility. You lift heavy loads using smaller chain sizes compared to lower grades. Uniform heat treatment ensures even load distribution across every link. Strength consistency matters because uneven links shorten service life. You benefit from predictable load response during repeated lifting cycles.

Strength characteristics

-

High tensile capacity

-

Stable elongation under load

-

Strong fatigue resistance

-

Controlled shock absorption

-

Uniform link performance

Grade 70 vs Grade 80 chain: what is the difference?

Grade 70 chain supports load binding and transport. Grade 80 lifting chain supports overhead lifting. You must never use Grade 70 chain for lifting because it lacks required strength and testing. Manufacturing standards separate these grades by alloy content and heat treatment. Using the correct grade protects safety and avoids inspection failure.

-

Grade 70 for tie-down use

-

Grade 80 for lifting use

-

Higher strength in Grade 80

-

Different markings

-

Different safety margins

Grade 80 vs Grade 100 Lifting Chain: How Do They Compare?

Grade 100 lifting chain provides higher strength than Grade 80 chain at the same diameter. You choose Grade 100 when weight reduction or higher capacity matters. Grade 80 remains widely used because of cost efficiency and broad availability. Manufacturers support both grades to match different lifting strategies and budgets.

-

Higher capacity in Grade 100

-

Wider market use for Grade 80

-

Different compatible fittings

-

Cost varies by grade

-

Application drives selection

How do you choose the right Grade 80 lifting chain size?

Chain size selection starts with accurate load calculation. You evaluate total load weight and sling geometry. Manufacturers publish load charts to support correct sizing. Incorrect chain size increases stress and shortens service life. Proper sizing improves safety and efficiency.

Selection criteria

-

Total lifted weight

-

Number of sling legs

-

Sling angle

-

Lift frequency

-

Environmental conditions

How should Grade 80 lifting chain be inspected?

Inspection keeps lifting operations safe and predictable. You inspect Grade 80 lifting chain before use and during service life. Visual checks reveal wear, cracks, and elongation early. Manufacturer markings help verify grade and size during inspections. Removing damaged chain prevents accidents.

Inspection focus

-

Link deformation

-

Surface cracks

-

Excessive wear

-

Heat discoloration

-

Missing markings