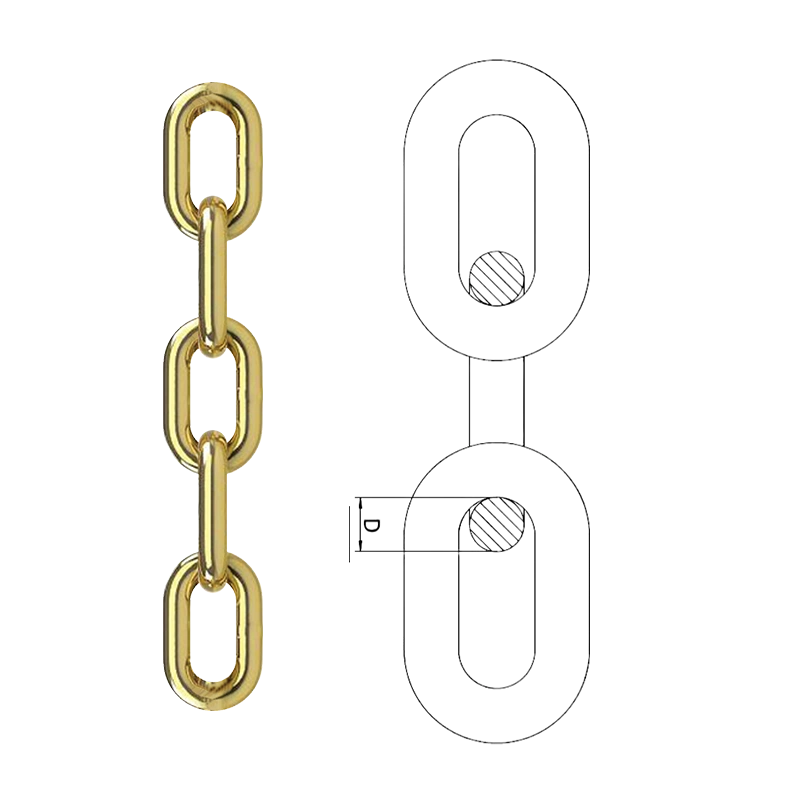

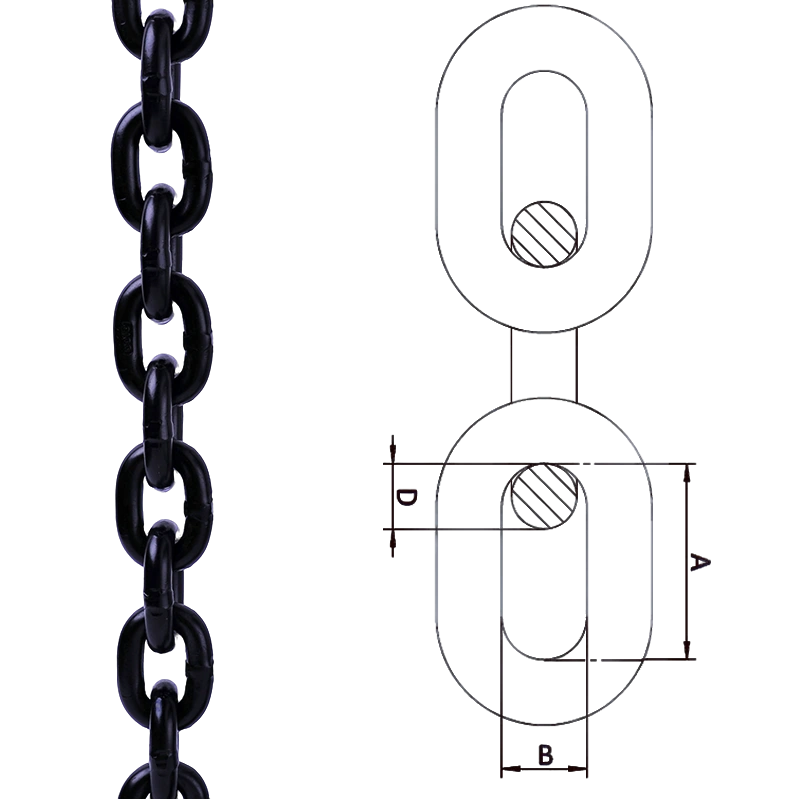

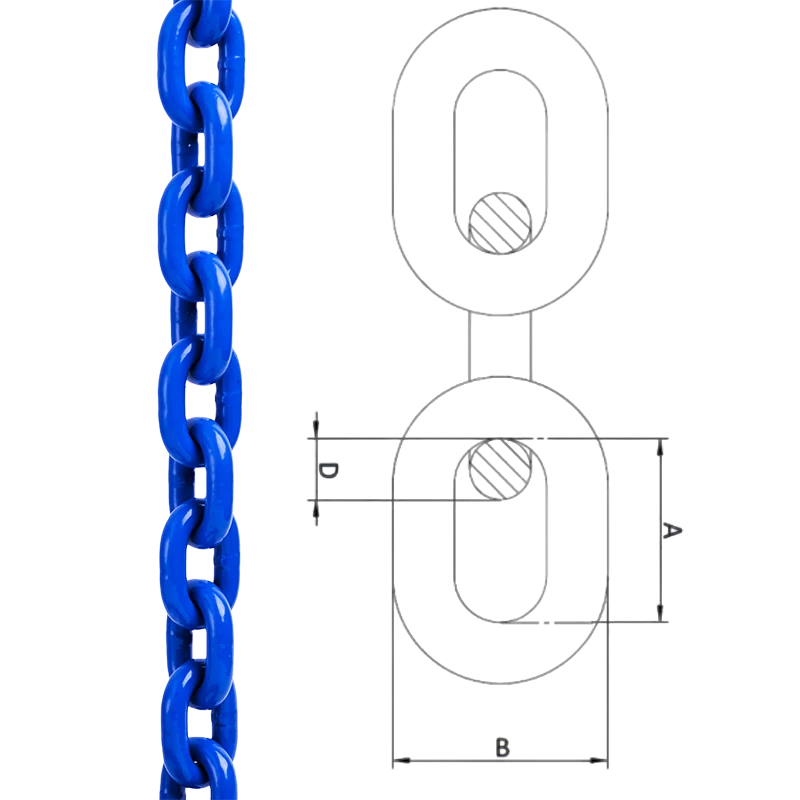

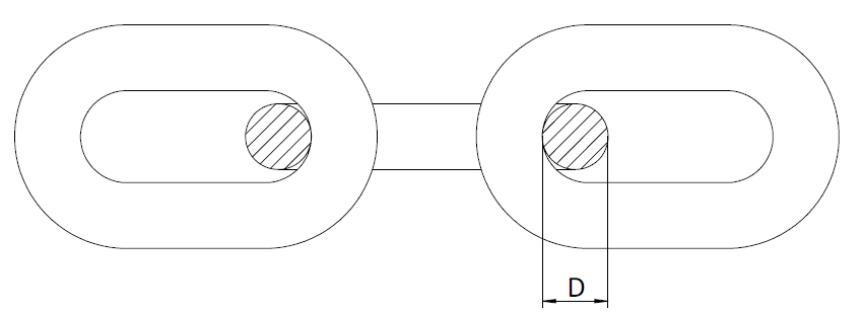

DIAGRAMS of GRADE 70 CHAIN

Grade 70 Transport Chain Specifications

| NOMINAL SIZE | MATERIAL DIAMETER | WORKING LOAD LIMIT | PROOF TEST(MIN) | BREAKING FORCE MIN | INSIDE LENGTH | INSIDE WIDTH | |||||||

| MM | IN | MM | IN | KG | LBS | KN | LBS | KN | LBS | MM | IN | MM | IN |

| 7 | 1/4 | 7 | 0.281 | 1430 | 3150 | 28 | 6300 | 56 | 12600 | 31.5 | 1.24 | 9.8 | 0.38 |

| 8.7 | 5/16 | 8.7 | 0.343 | 2130 | 4700 | 41.8 | 9400 | 83.6 | 18800 | 32.8 | 1.29 | 11.2 | 0.44 |

| 10 | 3/8 | 10.3 | 0.406 | 2990 | 6600 | 58.7 | 13200 | 117.4 | 26400 | 35 | 1.38 | 14 | 0.55 |

| 11.9 | 7/16 | 11.9 | 0.468 | 3970 | 8750 | 77.8 | 17500 | 155.4 | 35000 | 41.6 | 1.64 | 16.6 | 0.65 |

| 13 | 1/2 | 13.5 | 0.531 | 5130 | 11300 | 100.4 | 22600 | 200.8 | 45200 | 45.5 | 1.79 | 18.2 | 0.72 |

| 16 | 5/8 | 16 | 0.63 | 7170 | 15800 | 140.4 | 31600 | 280.8 | 63200 | 56 | 2.2 | 20 | 0.79 |

| 20 | 3/4 | 20 | 0.787 | 11200 | 24700 | 219.6 | 49400 | 439.2 | 98800 | 70 | 2.76 | 25 | 0.98 |

DESIGN of G70 CHAIN

TRANSPORT CHAIN GRADES

- G80

FINISH

- Yellow Zinc

STANDARDS

- Meets NACM & ASTM Standards.

HEAT TREATMENT

- Strength tested and heat treated for maximum safety and durability.

Design Factor

- 4:1

APPLICATION

- Designed for Use in Load Binding, Towing, Logging and Other Applications Requiring High Strength.

MATERIAL

- Made With High-Strength, Alloy Steel.

Our Advantages

Flexible Payment

Choose from a range of payment options to suit you such as a 30-day credit account.

Fast Delivery

Enjoy fast delivery with quick processing and timely arrivals for all your orders.

Best Rated

We Are the Highest Rated Lifting Chains Manufacturer in China With 20 Years of Experience & Knowledge

Price Match Guarantee

We are committed to offering the best prices and ensuring you never pay more than necessary.

FAQ of G70 TRANSPORT CHAIN

What is Grade 70 Chain?

Grade 70 chain is a heavy-duty steel chain, commonly used in load-securing applications. Made from heat-treated carbon steel, it’s known for its strength and durability. Grade 70 is designed to secure cargo during transportation and can handle tough industrial tasks, offering both reliability and cost-effectiveness.

G70 Chain Strength

G70 chain offers impressive tensile strength, with 9,300 lbs per 1/4-inch link. Its high strength-to-weight ratio makes it ideal for heavy-duty applications, such as cargo securing or towing. The chain’s tensile strength ensures that it can withstand significant force, minimizing wear and stretching over time.

Grade 43 vs Grade 70 Chain: What’s the Difference?

When choosing the right chain for your project, it’s essential to understand the key differences between Grade 43 and Grade 70 chains. Below is a breakdown of their features, uses, and benefits:

-

Material Composition:

-

Grade 43 Chain: Made from untreated steel, Grade 43 chains are designed for lighter-duty applications. They offer basic strength but are not heat-treated.

-

Grade 70 Chain: Heat-treated carbon steel makes Grade 70 chains stronger and more durable. This process ensures higher tensile strength, making it ideal for tougher applications.

-

-

Strength and Durability:

-

Grade 43 Chain: Best for general use in medium-duty tasks. It offers lower tensile strength and is prone to more wear and tear compared to Grade 70.

-

Grade 70 Chain: Known for its higher tensile strength, making it suitable for heavy-duty jobs like securing large loads or lifting. It’s much more durable and reliable for demanding work.

-

-

Applications:

-

Grade 43 Chain: Typically used in lighter applications, such as transporting smaller goods, tie-downs, and general industrial uses.

-

Grade 70 Chain: Preferred for securing heavy cargo, towing, or lifting. It’s commonly used in trucking, shipping, and construction industries where high strength is essential.

-

-

Cost Efficiency:

-

Grade 43 Chain: Lower cost, making it a good choice for lighter tasks that don’t require heavy lifting or securing.

-

Grade 70 Chain: While more expensive, it provides long-term value by offering higher strength and durability, making it a good investment for heavy-duty tasks.

-

-

Load Capacity:

-

Grade 43 Chain: Suitable for lower weight loads. It’s rated for less demanding uses where ultimate strength is not as critical.

-

Grade 70 Chain: Designed to handle much heavier loads. Its working load limits are significantly higher, making it ideal for industrial and construction uses.

-

Grade 70 vs Grade 80 Chain: Which is Stronger?

When choosing between Grade 70 and Grade 80 chains, it’s important to understand their differences in strength, durability, and applications. Here’s a detailed comparison:

-

Tensile Strength:

-

Grade 70 Chain: Offers strong tensile strength but is designed primarily for load securing and transportation tasks. It is strong enough for standard commercial and industrial uses.

-

Grade 80 Chain: Provides higher tensile strength than Grade 70, making it ideal for lifting applications that require more durability and resistance to stress.

-

-

Durability:

-

Grade 70 Chain: Durable and reliable for many medium-duty applications but not as resistant to wear as Grade 80. It’s designed for securing loads on trucks, trailers, or ships.

-

Grade 80 Chain: Built for heavy-duty lifting and is highly resistant to wear and tear. Its extra strength makes it ideal for demanding tasks that involve high levels of force.

-

-

Applications:

-

Grade 70 Chain: Commonly used for securing cargo, in logistics, or for towing. It is a trusted chain for tie-downs, securing heavy loads, and general industrial use.

-

Grade 80 Chain: Specifically designed for lifting applications, such as hoisting and rigging. It is frequently used in industries like construction, mining, and manufacturing where heavy lifting is required.

-

-

Weight Capacity:

-

Grade 70 Chain: Suitable for moderate load capacities. It’s perfect for cargo securement but not as capable of handling extreme loads compared to Grade 80.

-

Grade 80 Chain: Has a significantly higher weight capacity and is built to safely lift or carry heavier loads. It’s designed for tasks where high weight limits are a priority.

-

-

Cost:

-

Grade 70 Chain: Generally less expensive than Grade 80 due to its lower tensile strength and primary use for securing loads rather than lifting.

-

Grade 80 Chain: More expensive due to its higher strength and specialized use for lifting and rigging applications. It’s an investment for industries that require heavy-duty chains.

-

Grade 70 Chain Working Load Limit

Grade 70 chain’s working load limit (WLL) depends on the size, typically ranging from 2,600 lbs to 16,000 lbs for different link sizes. Always match the WLL to the weight of your cargo to ensure safety and prevent chain failure.

Grade 70 Chain Rating

The rating of Grade 70 chain is based on its tensile strength, with a minimum of 70,000 psi. It’s designed for tough, high-stress applications and is ideal for transportation and rigging tasks, where reliability and minimal stretch are critical.

How Do I Choose the Right Grade 70 Chain for My Application?

When selecting a Grade 70 chain, it’s essential to consider the following factors:

-

Weight of Your Load: Ensure the chain’s working load limit (WLL) exceeds the weight of the load you’re securing.

-

Environmental Conditions: Consider whether the chain will be exposed to extreme temperatures, moisture, or corrosive environments.

-

Application Requirements: Choose the chain size based on the weight of the load, as larger chains are required for heavier tasks.

Is Grade 70 Chain Suitable for Use in Marine Applications?

Grade 70 chain is not recommended for marine environments due to its susceptibility to rust. For marine applications, consider stainless steel or galvanized steel chains, which offer superior corrosion resistance in saltwater environments.

Can Grade 70 Chain Be Welded?

Yes, Grade 70 chain can be welded, but it requires specific techniques and equipment. Welding can alter the chain’s integrity, so use the proper heat treatment methods to maintain strength. Always consult the manufacturer’s guidelines for welding instructions.

How Should Grade 70 Chain Be Maintained?

Proper maintenance is crucial to ensure the longevity and performance of Grade 70 chains. Follow these steps:

-

Regular Inspections: Check the chain for any signs of damage, wear, or corrosion.

-

Cleaning: Clean the chain after each use to remove dirt, debris, and moisture.

-

Lubrication: Apply lubricant to the chain to prevent rust and ensure smooth operation.

-

Storage: Store the chain in a dry environment to avoid exposure to moisture and corrosive elements.

-

Replacement: Replace the chain if it shows signs of wear, such as stretched or damaged links.